High-Efficiency Thermal Management Solutions for Solar Energy Systems

Our photovoltaic inverter housings actively contribute to system efficiency through advanced thermal engineering. The combination of high-purity aluminum alloys and optimized geometrical designs creates exceptional heat dissipation characteristics, directly impacting power conversion efficiency and system longevity in demanding solar installations.

Energy System Advantages

• Active Thermal Regulation: Strategically designed cooling paths and surface areas maximize natural convection, reducing reliance on active cooling systems

• Environmental Protection: Multi-layer surface protection systems withstand UV degradation, temperature cycling, and corrosive atmospheric conditions

• EMI/RFI Containment: Unibody designs with continuous conductivity provide inherent electromagnetic shielding capabilities

• Installation Efficiency: Integrated mounting features, cable management options, and service access points streamline field installation

• Long-Term Reliability: Material selection and manufacturing processes ensure stable performance across 25+ year system lifecycles

Application-Specific Designs

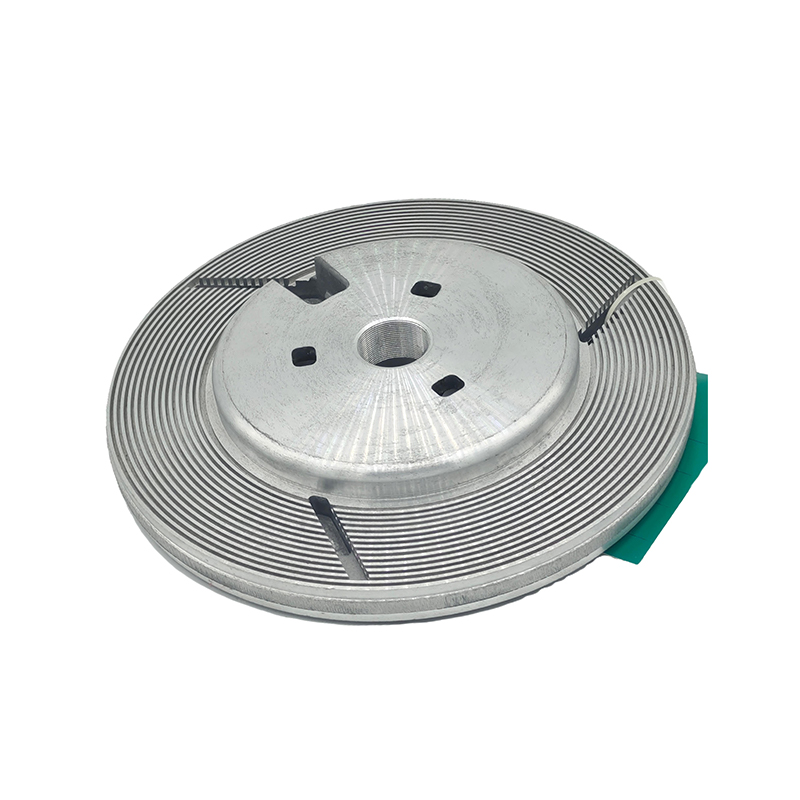

• String inverter housings with optimized heat sink geometries

• Microinverter enclosures featuring compact thermal management

• Combiner box bodies with integrated component mounting

• Power optimizer casings supporting various mounting configurations

Technical Manufacturing Capabilities

Our integrated approach combines high-pressure die casting with 5-axis CNC machining, achieving the flatness and surface quality requirements for optimal thermal interface performance. Dedicated quality stations verify thermal performance characteristics on a sampling basis.

Key Specifications

• Thermal Materials: AlSi10Mg, AlSi12, or high-conductivity variants

• Heat Dissipation Capacity: 50-300W depending on design configuration

• Surface Treatment: Chromate conversion, silver anodizing, or environmental coatings

• Protection Class: IP65, IP66 standard with IP68 options

• Compliance: UL 94V-0 flammability rating, RoHS compliance

English

English Español

Español Deutsch

Deutsch русский

русский