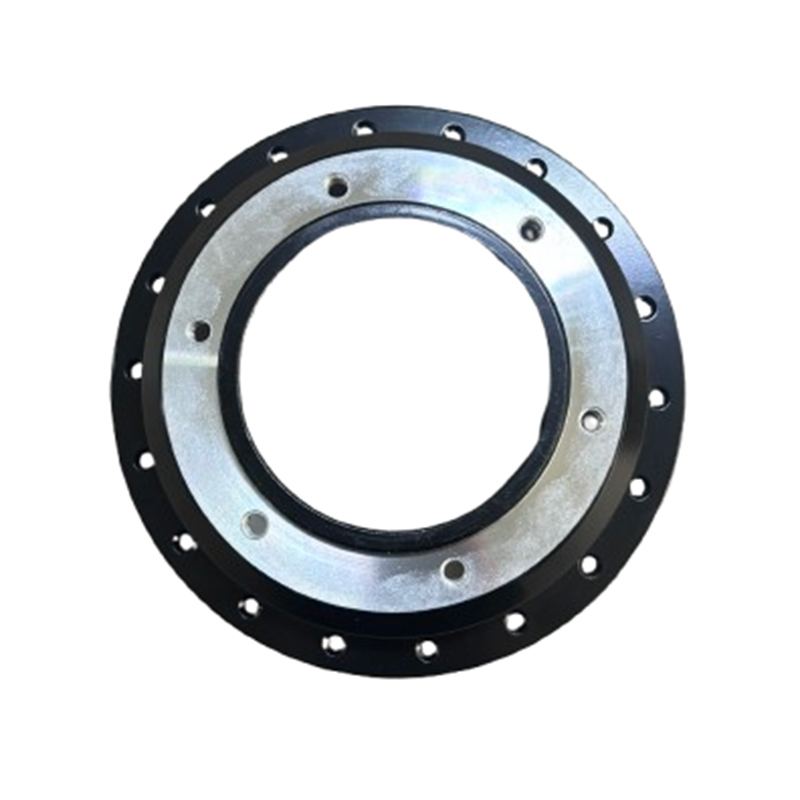

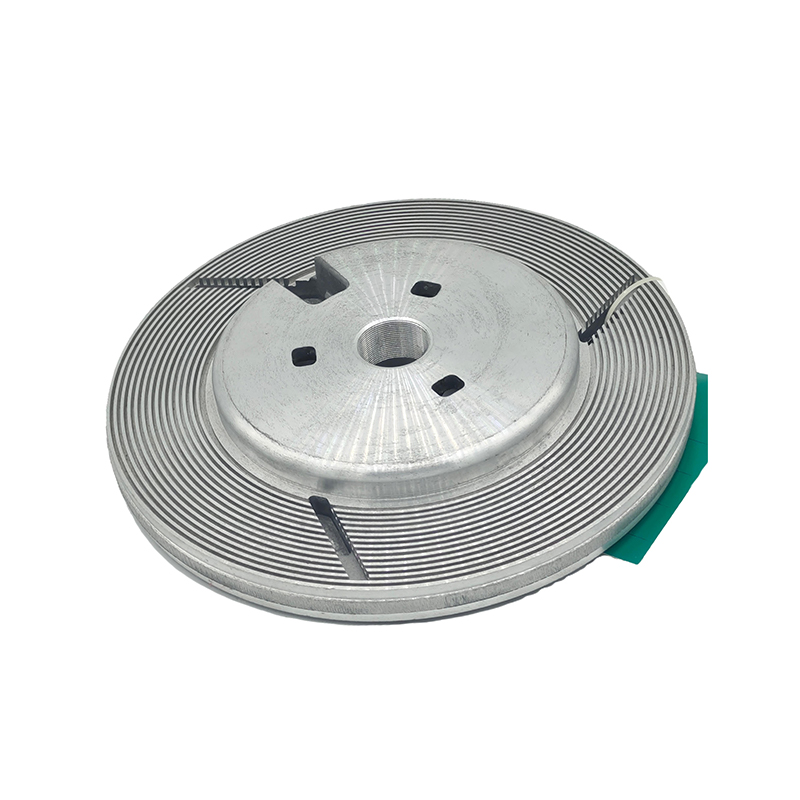

Bicycle Assist Motor Die-Cast Components are specialized parts designed for electric-assisted bicycles (e-bikes), enhancing motor efficiency and providing reliable housing for motor systems. These components utilize high-pressure die-casting with aluminum alloy, combining strength, lightweight design, and corrosion resistance for performance in various riding conditions. Here’s a brief overview:

Whether you want to become our partner or need our professional guidance or support in product selections and problem solutions, our experts are always ready to help within 12 hours globally.

Ningbo Jinyao Machinery Co., Ltd. is a China Surface-treated bicycle power-assist motor die-casting parts Suppliers and Surface-treated bicycle power-assist motor die-casting parts Factory. is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Spec...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is me...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes t...

-

Die Casting Mold Guide 2026: Components, Design & TypesView More

In the rapidly advancing manufacturing landscape of 2026, die casting technology remains the cornerstone for producing high-volume, dimensionally precise, and s...

-

How Do Engine System Die Castings Improve Strength and Durability in Modern Engines?View More

As modern engines continue to evolve toward higher efficiency, lighter weight, and longer service life, the demand for components with exceptional strength and ...

English

English Español

Español Deutsch

Deutsch русский

русский