Ningbo Jinyao Machinery Co., Ltd. is a China Die Cast Photovoltaic Inverter Housing Manufacturers and Photovoltaic Inverter Die Castings Suppliers. And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Photovoltaic inverter die castings Manufacturers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

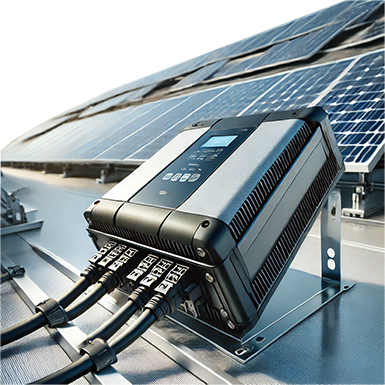

Photovoltaic inverter die castings are critical components used in the housing and heat dissipation structures of solar photovoltaic systems, commonly found in the enclosures, heat sinks, and other structural parts of inverters. Typically made from aluminum, these castings are produced using high-pressure die-casting processes. Aluminum alloy offers thermal conductivity, lightweight properties, corrosion resistance, and mechanical strength, allowing these castings to withstand harsh outdoor conditions such as high temperatures and moisture. Precision mold design ensures the efficient production of complex structures, enhancing both the cooling performance and structural integrity of the inverter.

Key performance features of photovoltaic inverter die castings include heat dissipation and protective properties. These castings efficiently dissipate the heat generated by the inverter during operation, ensuring stable performance even under heavy load conditions. They also provide robust protection against environmental factors such as moisture, dust, and corrosive elements, significantly extending the inverter’s service life. The lightweight design helps reduce installation complexity and maintenance costs. Additionally, optimized mold and production processes allow for dimensional stability and aesthetic appeal, meeting the modern photovoltaic inverter’s requirements for both high performance and sleek design.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

How does the die-casting process affect the thermal conductivity of photovoltaic inverter die-castings

In the modern photovoltaic industry, photovoltaic inverters are key equipment for converting solar energy into electrical energy. The performance of their internal components directly affects the efficiency and reliability of the entire system. Photovoltaic inverters usually contain a variety of complex electronic components and heat dissipation systems. Therefore, heat dissipation performance is crucial to improving their working efficiency. Among the many inverter components, the thermal conductivity of die-castings directly affects the heat dissipation performance of the inverter, thereby affecting its long-term operation stability and life.

The impact of die-casting process on thermal conductivity

Die-casting is a process in which molten metal is injected into a mold under high pressure and formed into a casting after cooling and solidification. For photovoltaic inverter die-castings, thermal conductivity is a key performance indicator, which is related to the efficiency of heat dissipation inside the inverter. Good thermal conductivity can help the inverter transfer heat from internal components to the outer shell faster, thereby ensuring that the equipment will not reduce efficiency or even damage due to overheating.

1. Selection of die-casting materials

In the die-casting process, the choice of materials is an important factor in determining thermal conductivity. Generally speaking, aluminum alloys are widely used in die castings for photovoltaic inverters due to their superior thermal conductivity and light weight. Aluminum alloy materials have high thermal conductivity and can effectively improve the heat dissipation performance of inverters. However, different formulations and compositions of aluminum alloys have different effects on their thermal conductivity. For example, adding elements such as silicon or copper may slightly reduce the thermal conductivity of aluminum alloys, but it is helpful in improving the strength and high temperature resistance of aluminum alloys. Therefore, how to balance these properties and select suitable aluminum alloy materials has become an important topic in die casting process design.

2. Optimization of die casting process

Ningbo Jinyao Machinery Co., Ltd., as a leading precision casting manufacturer in China, uses advanced vacuum technology, pin extrusion technology and high pressure point cooling technology to effectively optimize the casting process of aluminum alloys. The optimization of these processes can not only improve the appearance quality and dimensional accuracy of castings, but also improve the grain structure of aluminum alloys, thereby improving their thermal conductivity.

Vacuum technology: By using a vacuum environment in the die casting process, pores and inclusions in the casting can be reduced, which will affect thermal conductivity. Vacuum casting can obtain denser castings and improve the overall thermal conductivity of aluminum alloys.

Needle extrusion technology: This technology can form a more uniform metal flow on the surface of the casting, reduce the temperature difference between the inside and the outside, and further improve the thermal conductivity of the aluminum alloy. By optimizing the metal flow, the defects in the casting can be reduced, and the crystal quality of the aluminum alloy can be improved, thereby improving the thermal conductivity.

High-pressure point cooling technology: This technology allows the casting to cool quickly and evenly through precise cooling control during the die-casting process, reducing the thermal stress and deformation of the casting, thereby ensuring that the aluminum alloy maintains good thermal conductivity during the cooling process.

3. Structural design of castings

When designing photovoltaic inverter die-castings, reasonable structural design also has a direct impact on thermal conductivity. The wall thickness of the die-casting, the design of the cooling channel, and the structure of the heat dissipation surface can significantly affect its heat dissipation efficiency. Through precise structural design, the thermal conductivity of the aluminum alloy can be maximized to ensure that the inverter can dissipate heat efficiently.

Ningbo Jinyao Machinery Co., Ltd. focuses on precise mold design and structural optimization when designing die castings to ensure that aluminum alloy can effectively conduct heat. In addition, through in-depth understanding and analysis of the inverter cooling system, the company is able to provide customers with customized solutions that enable photovoltaic inverters to efficiently dissipate heat while maintaining good appearance and precision.

4. The impact of post-processing processes

Photovoltaic inverter die castings usually need to undergo a series of post-processing processes after casting, such as deburring, polishing, surface coating, etc. These post-processing processes can not only improve the appearance quality of the castings, but also improve the surface properties of the aluminum alloy and further improve the thermal conductivity. In particular, surface treatment can reduce the thermal resistance during heat conduction, thereby improving the heat dissipation efficiency of the inverter.

At Ningbo Jinyao Machinery Co., Ltd., precision machining and surface treatment processes ensure the high precision and high performance of castings, further enhancing the heat dissipation capacity of photovoltaic inverters.

Advantages of Ningbo Jinyao Machinery Co., Ltd. in the photovoltaic industry

As an enterprise integrating industry and trade, Ningbo Jinyao Machinery Co., Ltd. has rich experience in the field of precision castings. The company is committed to providing high-quality aluminum alloy die-castings for multiple industries such as photovoltaics, automobiles, communications, and engineering machinery. In the photovoltaic industry, Ningbo Jinyao Machinery Co., Ltd. has become a supplier of multiple international photovoltaic brands with its advanced die-casting technology and years of manufacturing experience.

The company uses advanced processes such as vacuum casting, needle extrusion, and high-pressure point cooling, which enable the company's photovoltaic inverter die-castings to have excellent thermal conductivity, reliable heat dissipation performance, and a long service life. In addition, Ningbo Jinyao Machinery Co., Ltd.'s precision machining plant is able to perform secondary processing on die-castings to meet customers' needs for complex structures and high precision.

How to avoid defects such as pores and cracks in photovoltaic inverter die-castings

As an important part of the solar power generation system, the photovoltaic inverter is responsible for converting solar energy into electrical energy. In order to ensure the efficiency and reliability of the photovoltaic inverter in long-term operation, its internal components must have good mechanical properties and high-quality manufacturing standards. Especially for the die castings of photovoltaic inverters, these parts usually need to withstand high temperatures, pressures and vibrations, so defects such as pores and cracks are prone to occur during their manufacturing process, which directly affect the heat dissipation performance and overall reliability of the inverter.

Therefore, how to avoid defects such as pores and cracks and ensure the quality of photovoltaic inverter die castings is a key issue in die casting production. Ningbo Jinyao Machinery Co., Ltd., as a leading precision casting manufacturer, has successfully overcome these problems with its rich experience in aluminum alloy die casting for many years and adopted advanced production processes and technologies to ensure the high quality and stability of photovoltaic inverter die castings.

1. Causes and prevention of pores

Porosity is one of the most common defects in the casting process, usually caused by the failure of gas to be discharged in time or gas being trapped inside the casting. The generation of pores is usually caused by the following factors:

Gas in the melt: Aluminum alloy melts easily absorb nitrogen and water vapor in the air at high temperatures. If these gases are not effectively discharged, pores will form inside the casting.

Improper mold design: If the exhaust system of the mold is not perfect, the molten metal cannot discharge the gas smoothly during the flow process, and the gas will be trapped in the casting.

Uneven cooling: If the cooling rate of the casting is uneven during the cooling process, the gas will be concentrated in certain areas, forming pores.

Ningbo Jinyao Machinery Co., Ltd.'s solution:

Ningbo Jinyao Machinery Co., Ltd. adopts advanced vacuum casting technology. By introducing a vacuum environment during the casting process, the presence of gas in the melt is effectively reduced, and the gas is further compressed during the casting process, thereby significantly reducing the occurrence of pores. Vacuum casting technology enables aluminum alloys to solidify in a bubble-free state, thereby improving the density and strength of the casting and ensuring its stability under high temperature and high pressure conditions.

In addition, the company also uses high-pressure point cooling technology to avoid the formation of pores caused by excessive temperature differences by precisely controlling the cooling process. This cooling method can ensure that the thermal stress of the casting is evenly distributed and reduce the probability of pore formation.

2. Causes and prevention of cracks

Cracks are another common and serious defect in the die casting process, which usually occurs during the cooling and solidification of the casting. The main causes of cracks are:

Thermal stress: During the cooling of the casting, the external cooling is faster than the internal cooling, resulting in a large temperature difference between the surface and the inside of the casting, which in turn generates thermal stress and may eventually lead to cracks.

Uneven materials: If the composition of the aluminum alloy material is unevenly distributed, or there is local overheating during the casting process, it may lead to uneven metal structure and reduce its crack resistance.

Mold design defects: Unreasonable mold design, especially improper cooling system design, can also lead to uneven cooling of the casting and increase the risk of cracks.

Solution of Ningbo Jinyao Machinery Co., Ltd.:

In order to avoid the occurrence of cracks, Ningbo Jinyao Machinery Co., Ltd. adopts precise mold design to ensure that the mold can evenly distribute the melt during the casting process to avoid overheating and excessive temperature differences. In addition, the company's high-pressure point cooling technology ensures the uniformity of aluminum alloy during the cooling process by controlling the temperature distribution of the cooling point, significantly reducing the generation of thermal stress, and thus effectively preventing the formation of cracks.

In order to further reduce the risk of cracks, Ningbo Jinyao Machinery also conducts precise composition control of aluminum alloy materials, adopts optimized alloy formulas and strict quality control processes to ensure the uniformity and stability of each batch of aluminum alloy materials, and fundamentally reduces the possibility of cracks.

3. Optimization of mold design and production process

Mold design is one of the key factors to avoid defects in die castings. Unreasonable mold design, especially in the design of cooling system and exhaust system, is prone to cause pores and cracks. In order to ensure the high quality of photovoltaic inverter die castings, Ningbo Jinyao Machinery Co., Ltd. pays special attention to mold design and optimization.

Exhaust system optimization: When designing the mold, Ningbo Jinyao Machinery Co., Ltd. rationally designed the exhaust channel according to the shape and characteristics of the casting to ensure that the gas in the melt can be quickly discharged, thereby preventing the generation of pores.

Cooling system optimization: In the design of the mold, the company precisely controls the position and structure of the cooling channel to make the cooling process more uniform and avoid cracks and internal stress caused by uneven cooling.

4. Post-processing process: further improve the quality of castings

The post-processing process of die castings also plays an important role in preventing pores and cracks. Ningbo Jinyao Machinery Co., Ltd. provides a variety of post-processing technologies for photovoltaic inverter die castings, including deburring, polishing, heat treatment, etc. These processes can further improve the surface quality of castings, improve the hardness of aluminum alloys, and increase their crack resistance.

Heat treatment: Through the heat treatment process, the grain structure of aluminum alloys is more uniform, thereby improving the strength and toughness of the material and reducing the occurrence of cracks.

Surface coating treatment: The company also provides high temperature and corrosion resistant coating treatment for castings, which effectively improves the overall stability and crack resistance of aluminum alloys.

5. The company's technical advantages in avoiding casting defects

As a leading precision casting manufacturer in China, Ningbo Jinyao Machinery Co., Ltd. has always been committed to technological innovation and process optimization in the production of photovoltaic inverter die castings. The company's vacuum casting, high-pressure point cooling and precision mold design technologies can effectively avoid the occurrence of common defects such as pores and cracks. With advanced production technology and strict quality control system, Ningbo Jinyao Machinery Co., Ltd. has provided high-quality die castings for many photovoltaic brands around the world and won wide market recognition.

English

English Español

Español Deutsch

Deutsch русский

русский

Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings