Ningbo Jinyao Machinery Co., Ltd. is a China Electric drive system die castings Suppliers and Electric drive system die castings Foundry . And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Electric drive system die castings Suppliers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

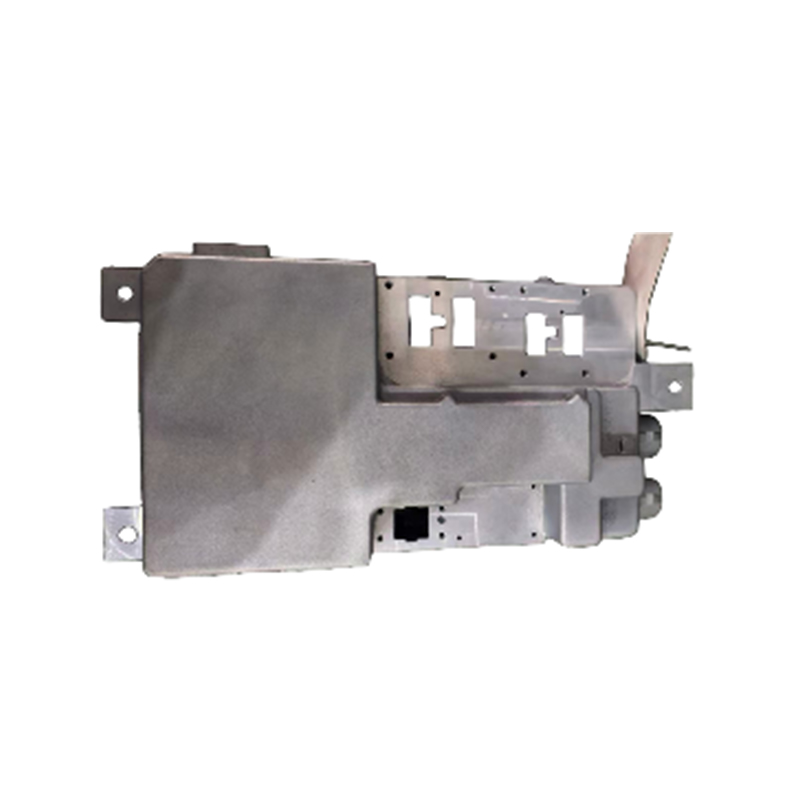

Electric drive system die castings are critical metal components used in electric drive systems, typically manufactured using lightweight materials such as aluminum alloys through high-pressure die-casting processes. These die castings play an essential role in providing structural support and functional protection within the electric drive system. They are required to possess high precision, high strength, thermal conductivity, and heat dissipation properties.

Electric drive system die castings usually feature complex geometries and precise dimensions to ensure a fit within key components such as electric motors and transmissions. These die castings must withstand high mechanical loads and environmental stresses while also offering good corrosion resistance and long-term durability to meet the stringent demands for durability and reliability in electric drive systems. Additionally, material lightweight is a key consideration in the design to enhance overall system efficiency.

These die castings are widely used in components such as electric motor housings, battery trays, and transmission casings in new energy vehicles (NEVs); in the electric drive systems of electric motorcycles, e-bikes, and other electric transportation tools; and also have certain applications in industrial automation, robotics, and other fields. Through precise mold design, high-pressure die-casting processes, and subsequent machining, the high quality and performance stability of these parts are ensured. Combined with strict quality control processes, electric drive system die castings provide reliable performance support for electric drive systems, helping to improve the overall energy efficiency and operational reliability of the vehicle.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

How the manufacturing accuracy of die castings in electric drive systems affects driving performance

As a core component of electric vehicles and other electric equipment, the performance of electric drive systems is directly related to the efficiency, reliability and user experience of the entire vehicle. One of the key components in the electric drive system, die castings, especially die castings made of aluminum alloy materials, has a crucial impact on driving performance. Especially in working environments such as high speed, high temperature and high pressure, the accuracy of die castings in electric drive systems not only affects the assembly accuracy of components, but is also directly related to thermal management, mechanical strength and overall driving efficiency.

Ningbo Jinyao Machinery Co., Ltd., as an enterprise focusing on the design and manufacture of aluminum alloy precision castings and high-pressure die casting molds, has provided high-quality electric drive system die castings with its many years of technical accumulation and advanced production processes. Its precision plays an important role in improving the performance of the drive system.

The relationship between manufacturing accuracy and driving performance

The electric drive system die castings usually include components such as motor housings, drive shafts, end covers, radiators, etc. These components carry important functions in electric drive systems. Insufficient manufacturing precision can lead to the following effects:

Reduced drive efficiency: The efficiency of motors and electronic control systems is highly dependent on the precision of their various mechanical components. Insufficient precision of die castings may cause the motor bearings to not be accurately docked or the motor housing and motor components to not fit well, thereby increasing friction resistance and causing reduced drive efficiency. Ningbo Jinyao Machinery Co., Ltd. uses advanced vacuum casting and high-pressure point cooling technologies, which effectively improve the surface finish and dimensional accuracy of castings, thereby ensuring the precise fit of drive components and improving system efficiency.

Thermal management issues: Die castings in electric drive systems often need to undertake thermal management tasks, especially motor housings and radiators. Insufficient precision of die castings may lead to uneven heat dissipation, affecting the effective release of heat, and thus affecting the heat dissipation effect of the motor. When die castings are of high precision, the surface is smooth and the structure is compact, which can better exchange heat, avoid overheating of the motor, and ensure the long-term stable operation of the system. Through high-precision casting, Ningbo Jinyao Machinery can ensure that the heat dissipation function of the electric drive system is maximized and the failure rate of the system is reduced.

Mechanical strength and stability: Many die castings in electric drive systems need to withstand large mechanical loads, such as motor housings and drive shafts. If the precision of die castings is not enough, it will lead to uneven material stress distribution, increase the risk of fatigue damage, and thus affect the long-term stability of the electric drive system. Ningbo Jinyao Machinery ensures better mechanical properties and higher durability of castings by precisely controlling casting parameters such as mold temperature and pressure during the design and manufacturing process of die castings.

Assembly accuracy and error accumulation: The electric drive system consists of multiple components, and the manufacturing error of any component will affect the overall assembly accuracy. Especially during precision assembly, the dimensional tolerance of die castings is too large, which may cause excessive gaps between components or loose fit, thus affecting the operating accuracy of the system. Ningbo Jinyao Machinery ensures the precise size and shape of castings through sophisticated mold design and advanced production processes, reduces the accumulation of errors from the source, and improves the fit accuracy during vehicle assembly.

Ningbo Jinyao Machinery's advantages in die casting manufacturing precision

Ningbo Jinyao Machinery Co., Ltd. provides high-precision aluminum alloy electric drive system die castings with its professional capabilities in precision casting and high-pressure die casting mold design. Here are several technical advantages of the company in manufacturing precision:

Advanced vacuum casting technology: By adopting vacuum casting technology, Ningbo Jinyao Machinery can significantly reduce defects such as pores and cracks in the casting process, thereby improving the density and strength of the castings. This technology ensures the reliability of die castings under high-speed operation and high-temperature environments, and improves the stability and durability of the electric drive system.

High-pressure point cooling technology: In order to further improve the precision and surface quality of castings, Ningbo Jinyao Machinery adopts high-pressure point cooling technology. This technology can speed up the cooling speed of castings, reduce stress deformation inside castings, ensure the dimensional accuracy of castings, and reduce the difficulty and cost of subsequent processing.

Precision mold design and manufacturing: As a professional mold design and manufacturing company, Ningbo Jinyao Machinery can customize high-precision and high-performance molds according to customer needs to ensure that each casting meets strict size and shape requirements. These precision molds not only improve production efficiency, but also greatly reduce the subsequent processing work of castings, so that die castings can reach high-precision standards in a shorter time.

Strict quality control system: Ningbo Jinyao Machinery has complete quality inspection equipment and a strict quality control system. From the selection of raw materials, the control of the production process to the inspection of finished products, every link is refined. The company uses technical means such as X-ray detection, ultrasonic detection, and three-coordinate measurement to ensure that the size, surface quality and mechanical properties of each die casting meet customer requirements.

How to control casting defects in the production process of electric drive system die castings

Q: How do casting defects affect product quality in the production process of electric drive system die castings?

A: Casting defects refer to defects in die castings that do not meet design requirements due to factors such as process, materials, and equipment during the casting process. For electric drive system die castings, common casting defects include pores, cracks, cold shuts, shrinkage, sand holes, etc. These defects not only affect the mechanical properties and appearance quality of castings, but may also affect the working efficiency and service life of electric drive systems. For example, pores can cause the density of the material to decrease, thus affecting its strength; cracks can cause the electric drive system to malfunction during use. To ensure the accuracy and reliability of die castings, these defects must be strictly controlled during the production process.

Q: How does Ningbo Jinyao Machinery control casting defects?

A: Ningbo Jinyao Machinery Co., Ltd. has taken a series of effective measures to control casting defects and ensure the high quality of electric drive system die castings with its many years of casting experience and advanced production technology. During the production process, we minimize the occurrence of casting defects by optimizing processes, controlling materials, using high-precision equipment, and conducting strict quality inspections. Specifically, we use the following methods to control common casting defects:

1. Use advanced vacuum casting technology

Vacuum casting technology is a process that reduces the gas content by extracting air during the casting process, which can significantly reduce defects such as pores and inclusions. Ningbo Jinyao Machinery applies this technology in the production of electric drive system die castings. Through vacuum casting, we can effectively reduce pores and sand holes in the casting process and improve the density and strength of the castings. Especially when producing high-demand aluminum alloy die castings, vacuum casting can ensure that there are no pores inside the castings, achieving higher density and mechanical properties.

2. Optimize casting mold design and manufacturing

Casting molds are one of the important factors affecting the quality of die castings. Ningbo Jinyao Machinery has a professional mold design and manufacturing team that can design high-precision molds according to the special requirements of electric drive systems. In the mold design process, we fully consider the fluidity, cooling effect and the rationality of the exhaust channel to ensure that the internal structure and appearance of the castings can meet strict quality standards. In addition, through the application of precision molds, we can effectively prevent the occurrence of defects such as cold shut and shrinkage, and improve the qualified rate of castings.

3. Adopt high-pressure point cooling technology

High-pressure point cooling technology is to improve the quality of castings by precisely controlling the cooling process of castings. Ningbo Jinyao Machinery uses high-pressure point cooling technology in the production process, which can speed up the cooling of castings and prevent defects such as shrinkage and cracks caused by uneven cooling. This technology reduces the temperature difference between the surface and the inside of the casting by pressurizing the coolant at a specific position, ensuring uniform cooling of the casting and improving the mechanical properties and appearance quality of the casting.

4. Strictly control the quality of casting materials

The quality of castings is directly related to the quality of the aluminum alloy materials used. Ningbo Jinyao Machinery strictly selects aluminum alloy materials that meet international standards, and each batch of materials will undergo strict quality inspections. We maintain long-term cooperation with the world's leading aluminum alloy suppliers to ensure that all aluminum alloy materials are precisely tested before production and meet the requirements of mechanical properties, chemical composition, etc. High-quality raw materials can not only effectively avoid inclusions and bubbles in castings, but also improve the corrosion resistance and oxidation resistance of castings, and ensure the stability of the electric drive system in long-term use.

5. Real-time monitoring and feedback during the process

Ningbo Jinyao Machinery has introduced an advanced real-time monitoring system in the production process, which can accurately control key parameters such as temperature, pressure, and flow during the casting process. By continuously adjusting process parameters, we can promptly detect potential problems and make adjustments during the production process to avoid defects. In addition, we have established a complete quality feedback mechanism, and professional personnel are responsible for quality control in every production link to ensure that each batch of die-castings produced meets the standards.

6. Strengthen quality inspection in the later stage

Even if multiple measures have been taken during the casting process, casting defects may still appear in the later stage. To this end, Ningbo Jinyao Machinery conducts strict quality inspections on each die casting after production is completed. We use advanced testing equipment such as X-ray testing, ultrasonic testing, three-coordinate measurement, etc. to comprehensively check the dimensions, internal defects, surface quality and other indicators of the castings. Through these testing methods, we can find any potential defects before the product leaves the factory, and make corrections or rework in time to ensure that each product meets the high standards of customers.

Q: How do these control measures of Ningbo Jinyao Machinery improve the overall performance of the electric drive system?

A: By adopting advanced casting technology and strict quality control, Ningbo Jinyao Machinery is able to produce high-precision and high-quality aluminum alloy die castings. These high-quality die castings can significantly improve the overall performance of the electric drive system. First, the density and mechanical properties of the castings are guaranteed, which can improve the operating efficiency and durability of the electric drive system. Secondly, the precision casting process ensures the precise fit of the components of the electric drive system, reduces the friction and energy loss caused by poor fit, and improves the efficiency of the drive system. Finally, high-quality aluminum alloy materials and high-precision casting surface treatment technology ensure the long-term and reliable operation of the electric drive system in harsh environments.

English

English Español

Español Deutsch

Deutsch русский

русский Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings