Ningbo Jinyao Machinery Co., Ltd. is a China Lightweight Aluminum Die Casting For Ecu Housing Manufacturers and New Energy Vehicle Die Casting Components Factory. And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

New Energy Automobile Die Castings Components Manufacturers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

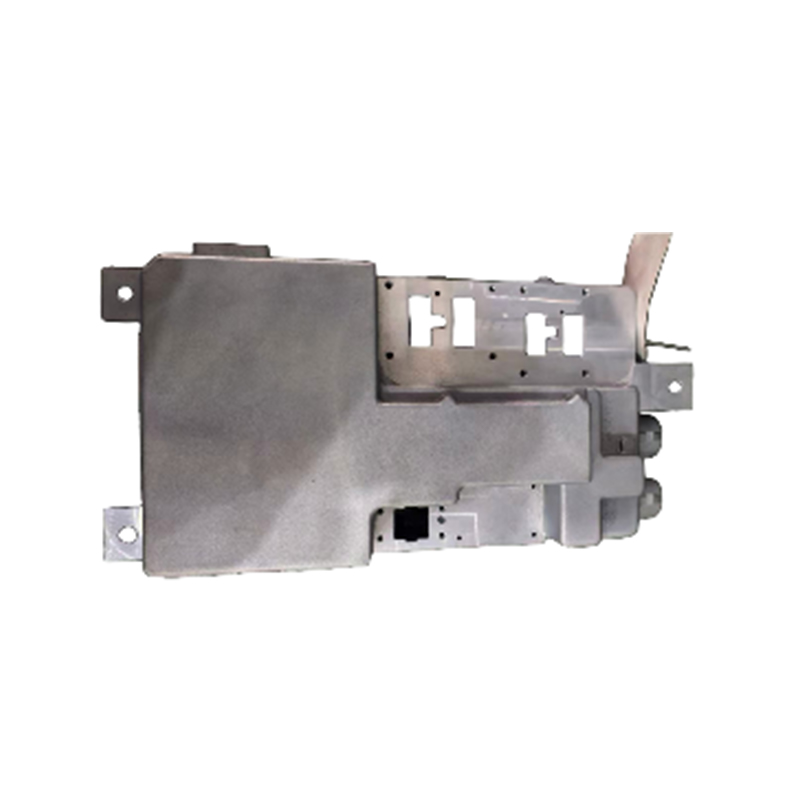

New energy automobile die castings are crucial metal parts in electric and hybrid vehicles, and are widely used in key parts such as battery housings, inverter housings, motor housings, and body structural parts and brackets. These die castings are mainly used to protect the core components of the vehicle, ensure the safe operation of batteries, motors, etc. under harsh working conditions, and optimize thermal management, improve the heat dissipation performance of the vehicle, and ensure the stability of the electric system.

Through advanced die-casting technology, new energy automobile die-casting parts can meet the strict requirements of automobile manufacturers on quality, performance and cost, providing solid support for the lightweight and high efficiency of new energy vehicles.

In short, new energy automobile die-casting has become a key technology to improve the performance and reliability of new energy vehicles due to its outstanding advantages in lightweight, high strength, high precision and efficient production, helping to promote the automotive industry to develop in a more environmentally friendly and efficient direction.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

The key role and development of new energy automobile die castings

New Energy Automobile Die Castings play a vital role in the manufacturing of new energy vehicles. As the global automotive industry transforms towards electrification and intelligence, the core components of new energy vehicles, such as battery systems, electric motors, body structures and chassis, have put forward higher requirements for die casting processes. These components not only need to have high strength and lightweight characteristics, but also high precision and good thermal management performance.

Ningbo Jinyao Machinery Co., Ltd. has achieved remarkable results in the production of new energy automobile die castings with its advanced equipment and rich production experience. The company provides a full range of die casting equipment, equipped with die casting machines, CNC milling machines and precision cutting equipment from world-renowned brands, which can meet the customized needs of various die castings in the production of new energy vehicles.

Application fields and technical requirements of die castings for new energy vehicles

New energy vehicles include electric vehicles (EV), plug-in hybrid vehicles (PHEV) and hydrogen fuel cell vehicles, etc. The application fields of their die castings cover multiple key components, including body structure, chassis, power battery system and motor components. The following are several major application fields of die castings for new energy vehicles:

Body and chassis structure

In the design of new energy vehicles, lightweight and strength improvement of body and chassis are key technical requirements. The use of New Energy Automobile Die Castings die casting process can integrate multiple parts, reduce weight and improve the overall performance of the vehicle. Aluminum alloy and magnesium alloy materials are widely used in the manufacture of body structural parts and chassis brackets because they are not only strong but also have low density.

Using the high-precision aluminum alloy die casting machine of Ningbo Jinyao Machinery Co., Ltd., in conjunction with the parts produced by the CNC machining center, it is possible to manufacture high-strength, low-weight body frames and chassis brackets to meet the strict requirements of new energy vehicles for lightweight. At the same time, the castings are post-processed by precision cutting equipment to further improve the surface quality and dimensional accuracy of the parts.

Battery system and thermal management components

The battery system is the heart of new energy vehicles, and the structure and heat dissipation system of the battery pack are crucial to the performance of the vehicle. New Energy Automobile Die Castings play an important role in the production of battery packs and battery management systems. Through New Energy Automobile Die Castings, high-precision battery housings, heat sinks, battery separators and other components can be produced to meet the multiple needs of lightweight, strength and thermal management.

Ningbo Jinyao Machinery Co., Ltd. uses fully automatic deburring systems and precision machining equipment to ensure the smoothness and dimensional accuracy of the surface of battery system components, thereby improving the heat dissipation effect, extending battery life and improving the endurance of electric vehicles.

Motor components

The motor is the power source of new energy vehicles. The manufacturing of the motor requires high precision and high performance, especially in the production process of stators, rotors and housings. Die casting technology can efficiently manufacture various components of the motor to ensure its reliability and durability under high load and high temperature environments.

Ningbo Jinyao Machinery Co., Ltd. provides a variety of die casting machines from 280 tons to 2500 tons, which can meet the production needs of motor components of different specifications. During the production process, the company combines high-precision CNC milling machines and surface treatment equipment such as horizontal polishing and vibration grinding to ensure the smooth surface of each motor component and ensure the high efficiency and stability of the motor.

New Energy Automobile Die Castings" Production Process and Technical Advantages

The production of New Energy Automobile Die Castings requires not only high-precision die-casting machines, but also precise post-processing processes to ensure the quality of parts. Ningbo Jinyao Machinery Co., Ltd. has a complete production line and high-precision equipment to meet the strict requirements of new energy vehicle manufacturing for die-casting parts.

High-precision die-casting and efficient production

Ningbo Jinyao Machinery Co., Ltd. has introduced die-casting equipment from world-renowned brands, covering medium to large die-casting machines, which can meet the production needs of various new energy vehicle parts. Whether it is body structure parts, chassis brackets or battery pack shells, the company's die-casting equipment can provide precise casting results.

The company is also equipped with CNC milling machines and precision cutting equipment from Japan's Makino, Brother and the United States' Wheeler. These high-precision equipment ensures the machining accuracy of castings and ensures that the dimensional tolerance of each component meets the standards for new energy vehicle production.

Post-processing and surface treatment technology

The surface treatment of new energy vehicle die castings is crucial to their appearance, corrosion resistance and long-term performance. Ningbo Jinyao Machinery Co., Ltd. has a full range of surface treatment equipment, including hanging polishing, horizontal polishing and vibration grinding, which can meet the surface smoothness requirements of different types of castings.

Hanging polishing and horizontal polishing: used to improve the surface finish of aluminum alloy die castings and avoid defects in the appearance of the vehicle.

Vibration grinding: By removing burrs on the surface of the casting during the vibration grinding process, the overall surface quality and precision of the casting are improved.

This series of surface treatment processes not only improves the aesthetics of die castings, but also enhances their corrosion resistance and wear resistance, and is particularly suitable for the exterior and chassis components of electric vehicles.

Automation and flexible production line

In order to improve production efficiency, Ningbo Jinyao Machinery Co., Ltd. introduced a flexible automated deburring system and precision cutting equipment on the production line. The automated deburring system can automatically remove burrs and excess parts after casting production, avoiding the inefficiency and errors of manual deburring. At the same time, precision cutting and processing equipment can be customized according to different parts requirements, greatly improving the flexibility and efficiency of production.

English

English Español

Español Deutsch

Deutsch русский

русский

Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings