Ningbo Jinyao Machinery Co., Ltd. is a China Die Cast Motorcycle Accessories Manufacturers and Motorcycle Accessories Die Castings Factory. And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Motorcycle accessories die castings Manufacturers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

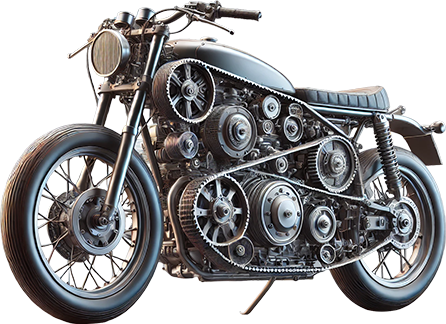

Motorcycle accessories die castings hold an essential place in motorcycle manufacturing.

These die-cast components are produced through the die-casting process and exhibit several notable features. First, they offer high precision. The die-casting process produces parts with tight dimensional accuracy and smooth surface finishes, perfectly meeting the strict precision requirements of motorcycle accessories. Second, they possess high strength. Motorcycle accessories die castings are typically made from aluminum alloys or other metals, providing the necessary strength and hardness to withstand the various stresses encountered during motorcycle operation. Additionally, die casting offers high production efficiency, allowing automation to rapidly meet the large-scale production demands of the motorcycle industry.

A wide variety of motorcycle accessories use die castings. Engine housings are a critical component, and using die castings can improve heat dissipation and sealing performance. Wheel hubs, often made from aluminum alloy die castings, are lightweight, strong, and aesthetically pleasing. Brake system components such as brake discs and calipers benefit from die castings, which ensure the precision and strength needed for braking performance. Transmission system parts like sprockets and gears are also made from die castings, enhancing the accuracy and reliability of the transmission system.

In terms of quality control, several factors need to be considered. High-quality raw materials like aluminum alloys should be selected to ensure the foundation of the die castings’ quality. The die-casting process must be carefully controlled, with parameters such as pressure, temperature, and speed managed to ensure consistent quality. Additionally, rigorous quality inspections, including dimensional, visual, and mechanical performance checks, should be conducted to ensure that the die castings meet the required standards.

In conclusion, motorcycle accessories die castings are critical to the performance and safety of motorcycles, and their quality must be strictly controlled throughout production and use.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

English

English Español

Español Deutsch

Deutsch русский

русский

Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings