Ningbo Jinyao Machinery Co., Ltd. is a China Mold manufacturing Manufacturers and Mold manufacturing Suppliers . And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Mold manufacturing Manufacturers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

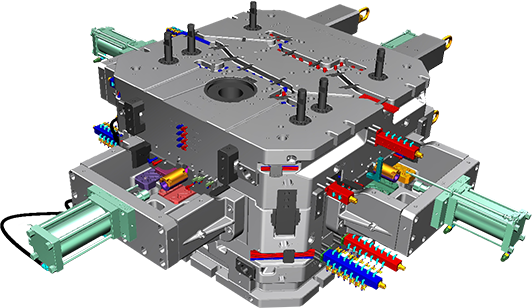

Mold manufacturing, as an important cornerstone of modern industrial production, is a field of precision manufacturing that combines exquisite craftsmanship, advanced technology, and innovative design.

The mold manufacturing process is complex and delicate, from the initial design concept to material selection, processing, assembly, and debugging, each link requires a high degree of professional knowledge and rigorous operation.

During the design phase, experienced engineers use advanced CAD, UG, and other software, combined with the needs and characteristics of the product, to carefully plan the structure and size of the mold to ensure that it can efficiently and accurately produce parts that meet the requirements.

In terms of material selection, high-strength, high-wear-resistant, and corrosion-resistant high-quality materials such as mold steel and aluminum alloy are selected according to the use environment and life requirements of the mold.

The processing link is the core of mold manufacturing. Using advanced equipment such as CNC machine tools, EDM, wire cutting, etc., the mold is finely processed by cutting, drilling, grinding, etc. to achieve precise shapes and sizes.

During the assembly process, each component is accurately combined in strict accordance with the design requirements to ensure smooth movement and close fit of the mold.

During the debugging phase, the mold is tested and optimized, and the parameters are continuously adjusted until the product produced reaches the ideal quality and precision.

The application fields of mold manufacturing are extremely wide. In automobile manufacturing, molds are used to produce body panels, engine parts, etc.; in the electronics industry, they are used to manufacture various types of precision plastic and metal shells; in the field of home appliances, they provide guarantees for the production of products with exquisite appearance and complex structures.

In mold manufacturing, the advantages of die-casting molds are highlighted. First of all, die-casting mold manufacturing can achieve large-scale, high-efficiency batch production, greatly improve production efficiency, and significantly reduce production costs. Secondly, the die-casting mold produced has precision, and the formed parts have precise dimensions and surface quality, which greatly reduces subsequent processing steps. Furthermore, the flexibility of die-casting mold manufacturing allows the production of parts with complex structures and unique shapes, fully meeting diverse design needs. In addition, sophisticated die-casting mold manufacturing also has a high degree of stability and reliability, and can maintain stable and performance during long-term continuous production.

Our mold manufacturing team has professional technical personnel, advanced equipment, and a complete quality management system. We are committed to providing customers with high-quality, high-precision, high-performance mold products to meet the diverse needs of different industries and promote the efficient development of industrial production.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

English

English Español

Español Deutsch

Deutsch русский

русский

Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings