Ningbo Jinyao Machinery Co., Ltd. is a China Steering system die castings Suppliers and Steering system die castings Foundry . And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Steering system die castings Suppliers

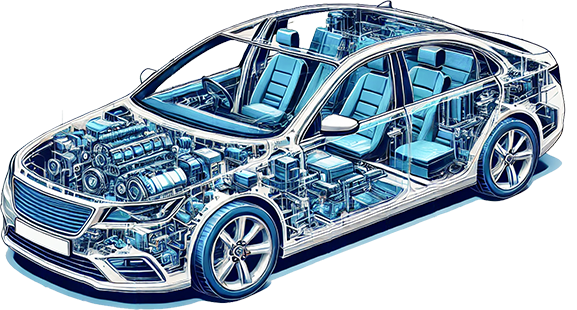

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

Steering system die castings are a vital component in the precise system of automobile operation. As a professional factory integrating mold development, high-pressure die casting, and fine processing, we carefully create high-quality steering system die castings for you.

Steering system die castings are widely used and critical. They constitute the core structure of the steering system, such as the steering gear housing, steering column, n, and other components, ensuring that the driver's steering instructions can be accurately transmitted and providing strong support for the smooth steering of the vehicle.

Functionally, steering system die castings perform excellently. They can effectively withstand various complex stresses and frequent vibrations during vehicle driving, ensuring the stable operation of the steering system. At the same time, they have a sealing performance, preventing the intrusion of impurities and dust, and maintaining the cleanliness and good lubrication of the internal environment.

Core performance is the key advantage of steering system die castings. High strength and hardness make them durable and not easy to deform under harsh working conditions. Precise size and shape control ensures close fit with other parts, greatly improving steering accuracy and sensitivity. Our steering system die-casting products have outstanding highlights.

Advanced mold design and manufacturing lay the foundation for the complex shape and high precision of die castings. High-pressure die-casting technology gives the product internal structure and surface quality. The fine processing links further improve the precision and performance of steering system die castings.

For example, our carefully crafted steering gear housing steering system die castings, with their unique structural design and high-quality materials, effectively improve the working efficiency and reliability of the steering system. Similarly, the precisely manufactured steering column steering system die castings bring drivers a smoother and more comfortable steering experience. Choosing our steering system die castings means choosing safe, accurate, and reliable driving protection. We will continue to work hard to provide you with better steering system die castings.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

What are Steering System Die Castings?

Steering System Die Castings are an indispensable component of modern automotive steering systems. With the advancement of automotive industry technology, the requirements for steering systems are increasing, including higher strength, higher precision, and lighter weight. To meet these needs, die casting, as an efficient and precise manufacturing technology, is widely used in the production of automotive steering systems.

Steering System Die Castings are metal parts for steering systems manufactured by die casting. The steering system includes important components such as steering gears, steering arms, steering wheel bearings, steering columns, etc. These components are usually die-casted with high-strength materials such as aluminum alloys and zinc alloys to ensure their durability and safety in complex driving environments.

At Ningbo Jinyao Machinery Co., Ltd., we use advanced die-casting technology and equipment, combined with superb mold design and manufacturing capabilities, to produce Steering System Die Castings that meet global standards. Our professional design team is proficient in various mold flow analysis software to ensure that every parameter in the die casting process is optimally set to ensure high precision and excellent performance of the product.

Why do steering systems need die castings?

Precision and complexity

The components of the steering system require high-precision manufacturing to ensure that they can accurately transmit the driver's control signals while ensuring the stability and safety of the steering system. The die-casting process enables the production of complex shapes in a shorter time while ensuring high dimensional accuracy. Through mold flow analysis (Moldflow) technology, we can optimize material flow and improve the filling and density of components, thereby improving the quality of steering system die castings.

When designing the mold, the design team of Ningbo Jinyao Machinery Co., Ltd. comprehensively considered various factors such as pressure, temperature, speed, etc. to ensure that the strength and quality of the die castings meet the standards. Our optimized design of the mold makes the die castings have better stability and lower defect rate, further improving the performance of the steering system.

High strength and durability

The various components in the steering system are usually subject to large loads, especially when driving at high speeds or making sharp turns, the components of the steering system need to withstand huge mechanical stress. Die casting using metal materials such as aluminum alloys and zinc alloys can provide the necessary strength and rigidity to ensure the stability and durability of the components under high loads.

By precisely controlling various parameters in the die casting process (such as pressure, temperature, cooling rate), we can effectively control the internal structure of the components and ensure that they have high tensile strength, fatigue strength and good corrosion resistance.

Save materials and costs

The die casting process reduces material waste and improves production efficiency by precisely controlling the flow of materials. Compared with traditional casting and forging processes, the die casting process can produce steering system components with complex shapes and high precision at a lower cost. Ningbo Jinyao Machinery Co., Ltd. strictly controls the amount of materials and processing costs during the production process, so that customers can enjoy lower production costs while ensuring product quality.

Application of Steering System Die Castings

Steering system die castings are an indispensable part of the automotive steering system. They include key components such as steering gears, steering arms, steering wheel bearings and steering columns. Here are some common applications:

Steering gear: The steering gear is a key component that transmits the turning force applied by the driver through the steering wheel to the wheels. The steering gear is usually made of aluminum alloy or zinc alloy and is produced by die casting. By optimizing the mold design and precisely controlling the die-casting process, Ningbo Jinyao Machinery Co., Ltd. is able to produce steering gears with high strength, precise dimensions and excellent corrosion resistance, ensuring its reliability in long-term use.

Steering arm: The steering arm is responsible for transmitting the rotational force in the steering system to the wheels. It usually needs to withstand large shear and bending forces, so its strength requirements are high. By adopting the die-casting process, the steering arm can not only maintain a low weight, but also have high strength and rigidity to ensure the safety of the steering system.

Steering wheel bearing: The steering wheel bearing is an indispensable component in the steering system, responsible for supporting the rotation of the steering wheel and ensuring smooth operation. The bearing components produced by the die-casting process have high dimensional accuracy and surface finish, which can ensure smooth rotation of the steering wheel and improve the driving experience.

Steering column: The steering column is an important component that connects the steering wheel and other components of the steering system, and usually requires high strength and durability. By using materials such as aluminum alloy or zinc alloy for die-casting, the weight of the steering column can be effectively reduced while ensuring its sufficient strength and stability.

Technical advantages of Ningbo Jinyao Machinery Co., Ltd. in Steering System Die Castings

Since its establishment, Ningbo Jinyao Machinery Co., Ltd. has focused on the research and development and production of high-precision die castings, especially in the field of Steering System Die Castings. Our professional design team has the following technical advantages:

Mold flow analysis and design software application: We are proficient in mold flow analysis software and design software, and can accurately predict and optimize the flow and filling process of die castings to ensure the rationality and production efficiency of mold design.

Precise control of die casting process: We accurately adjust process parameters such as pressure, temperature, cooling speed, etc. during the die casting process to ensure that the steering system components have the best strength, precision and surface quality.

Mold material selection and process optimization: Our design team has rich experience in mold material selection and can select the most suitable mold material according to the requirements of different steering system components to ensure the high quality of die castings.

Equipment control and maintenance: We have comprehensive control and maintenance experience for die casting equipment, which can ensure the long-term stable operation of the equipment, improve production efficiency, and ensure delivery time.

Quality inspection and control: We use advanced quality inspection methods to ensure that each steering system die casting can meet international quality standards, including size, strength, surface quality and other aspects.

English

English Español

Español Deutsch

Deutsch русский

русский Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings