Ningbo Jinyao Machinery Co., Ltd. is a China Inspired motor die castings Suppliers and Inspired motor die castings Foundry . And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Inspired motor die castings Suppliers

- Traditional automobile die castings

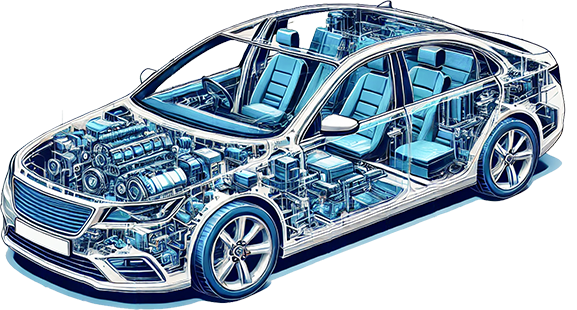

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

Induction motor die casting is an important part of the induction motor.

Its purpose is to form the key parts of the starting generator, such as end covers, housings, stator mounting sleeves, transmission flanges, etc. These die castings provide support for the stable operation and efficient performance of the starting generator.

In terms of function, starting generator motor die-casting can ensure the tight connection and good sealing performance of the internal structure of the motor, which helps to prevent leakage, dust, etc., and protect the precision components inside the motor.

In terms of core performance, they usually have high strength and hardness to withstand the various forces and pressures generated when the motor is running. At the same time, they have good wear resistance and corrosion resistance and can maintain stable performance during long-term use.

In order to achieve these properties, advanced die-casting processes and precision mold manufacturing technology are used in the production of starting generator motor die-castings. By optimizing the mold design and die-casting parameters, the die-casting parts can have precise size and shape to ensure coordination with other motor components. In terms of material selection, suitable aluminum alloy materials are generally selected to meet the requirements of strength, conductivity, etc.

For example, the precision of the internal structure and surface quality of the die-cast end cap directly affect the overall performance of the motor. Carefully designed shapes and sizes can ensure tight installation with other parts of the motor, improving the operating efficiency and stability of the motor.

In addition, some starting generator motor die castings may also be specially treated or designed to further improve their performance. For example, in order to enhance the heat dissipation effect, heat dissipation fins may be designed on the surface of the die casting; or in order to improve the insulation performance, special coating treatment may be used.

In short, the quality and performance of starting generator motor die castings play a vital role in the normal operation, efficiency, and reliability of starting generator motors. Their manufacturing requires strict process control and quality inspection to ensure that they meet various stringent requirements.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

What is "Inspired Motor Die Castings"?

Motor Die Castings are key components manufactured through high-precision casting processes and are widely used in electric motors, motors and various power equipment. Motor castings are usually made of metal alloy materials such as aluminum, zinc, magnesium, and copper. These materials have good thermal conductivity, strength, lightweight characteristics and corrosion resistance, so they are widely used in many fields such as home appliances, power tools, electric vehicles and industrial equipment.

Motor Die Castings use molds to inject molten metal into a precise mold cavity at high speed to form the required parts. This casting process ensures that the casting has a high degree of precision and good surface quality by precisely controlling the temperature, injection pressure and casting time. In addition, the casting process can reduce material waste and improve production efficiency. It is an efficient and low-cost large-scale production method.

In terms of Inspired Motor Die Castings, through innovative design and manufacturing processes, the performance, weight, heat dissipation and cost of motor castings are continuously optimized to meet the needs of modern equipment for high efficiency and lightness.

Since its establishment in 1995, Ningbo Jinyao Machinery Co., Ltd. has been focusing on providing customers with customized casting mold solutions, covering the entire process from mold design, sample development to product production. Whether it is rapid mold making or mass production with precise tolerances, Ningbo Jinyao Machinery Co., Ltd. can provide customers with efficient and economical solutions with its rich experience and professional team.

Functions and Applications of Inspired Motor Die Castings

Inspired Motor Die Castings play a vital role in many industries. They are usually used to manufacture key components such as motor housing, stator, rotor and cooling system.

1. Home Appliance Industry: Inspired Motor Die Castings are widely used in home appliances, such as air conditioners, refrigerators, washing machines, electric fans, etc. The housing and structural components of the motor are generally made of aluminum alloy or zinc alloy castings. These materials not only have excellent heat dissipation, but also reduce the overall weight of the product, thereby improving energy efficiency and extending the life of the equipment.

2. Power Tools: Power tools, such as electric drills, electric saws, angle grinders, etc., usually need to withstand high loads, so Inspired Motor Die Castings play an important role in these tools. To ensure their high strength and durability, aluminum alloy and magnesium alloy materials are widely used in the structural components of these motors.

3. Electric and Hybrid Vehicles: The widespread popularity of electric vehicles (EV) and hybrid vehicles (HEV) has greatly increased the demand for Inspired Motor Die Castings. These vehicles rely on efficient motors, and the heat dissipation and lightweight of Inspired Motor Die Castings are crucial to the performance improvement of electric vehicles. Ningbo Jinyao Machinery Co., Ltd. is able to provide customers with high-quality casting molds suitable for the electric vehicle field and achieve high-precision, large-scale casting production.

4. Industrial Applications: Large industrial equipment, such as robots, wind turbines, and high-power industrial motors, usually require high-performance Inspired Motor Die Castings to ensure the efficient operation of the equipment. Inspired Motor Die Castings not only provide structural strength, but also effectively manage the heat of the equipment during operation, thereby improving the stability and reliability of the system.

Through the customized molds and high-precision casting solutions provided by Ningbo Jinyao Machinery Co., Ltd., these industries can obtain high-quality, low-cost and superior performance Inspired Motor Die Castings. The company can produce up to 250 casting molds per year to ensure that the needs of large-scale production are met.

Innovative Technology and Future Development of Inspired Motor Die Castings

With the increasing market demand for Inspired Motor Die Castings, innovative design and technology are driving the development of this field. Modern Inspired Motor Die Castings not only focus on product performance, but also focus on improvements in energy saving, environmental protection and intelligent production. The following are some trends in technological innovation and future development:

1. Application of advanced materials: Traditional Inspired Motor Die Castings mostly use materials such as aluminum alloys and zinc alloys, but with the increasing market demand for high performance and lightweight, new alloy materials such as magnesium alloys, copper alloys and ceramics are gradually being used in the production of Inspired Motor Die Castings. These new materials not only have lighter weight and better heat dissipation performance, but also provide higher corrosion resistance and high temperature resistance.

2. 3D printing and precision casting: The introduction of 3D printing technology makes the design of Inspired Motor Die Castings more flexible and sophisticated. Through 3D printing, complex structures and shapes that are difficult to achieve with traditional casting processes can be manufactured, which not only improves the functionality of motor parts, but also greatly shortens the production cycle and saves raw materials.

3. Environmentally friendly casting process: With the improvement of global environmental protection requirements, the casting industry is also constantly adopting more environmentally friendly technologies and processes. Ningbo Jinyao Machinery Co., Ltd. has significantly reduced exhaust emissions and energy consumption by optimizing the production process and introducing high-efficiency and environmentally friendly technologies such as low-pressure casting. The company also pays attention to the use of environmentally friendly materials in the mold production process to ensure compliance with international environmental standards.

4. Intelligent production and automated control: With the development of Industry 4.0, intelligence and automation have become the main trends in the production of Inspired Motor Die Castings. By integrating advanced sensors, artificial intelligence and big data analysis, Ningbo Jinyao Machinery Co., Ltd. is able to achieve precise control in the production process, improve product quality and reduce manufacturing costs.

5. More efficient thermal management technology: Modern motors, especially in high-power applications, need to have more efficient heat dissipation capabilities. To this end, Ningbo Jinyao Machinery Co., Ltd. continues to innovate in casting molds and material selection, using more efficient thermal conductivity materials and optimized designs to ensure stable operation of the motor and avoid failures caused by overheating.

English

English Español

Español Deutsch

Deutsch русский

русский Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings