Ningbo Jinyao Machinery Co., Ltd. is a China Engine system die castings Suppliers and Engine system die castings Foundry . And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Engine system die castings Suppliers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

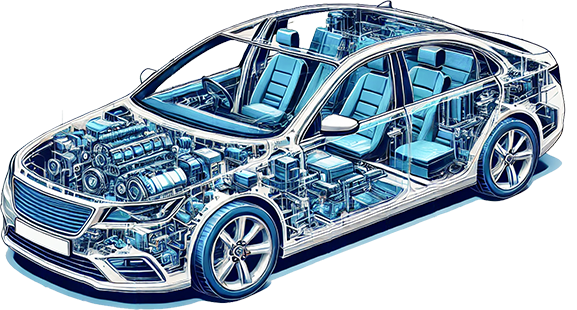

In the core field of automotive power, engine system die castings occupy a pivotal position. As a professional factory integrating molds, high-pressure die casting, and processing technology, we focus on creating engine system die castings for you.

The uses of engine system die castings are extremely critical and diverse. They constitute the core structure of the engine, such as the cylinder block and cylinder head, providing a solid foundation for combustion and power transmission. In addition, engine system die castings such as intake pipes and exhaust pipes ensure the smooth flow of gas and optimize the entire combustion process.

In terms of functionality, engine system die castings perform well. They can effectively withstand high temperatures, high-pressure environments, and complex mechanical stress inside the engine. At the same time, their sealing performance ensures leakage-free operation of oil, fuel, and gas.

Core performance is the highlight of die castings in engine systems. High strength and hardness make it stable and durable under working conditions. Good thermal conductivity helps to dissipate heat quickly and improve the working efficiency and stability of the engine. Precise size and shape control ensures precise coordination with other parts.

Our range of die-cast parts for engine systems has many highlights. Advanced high-pressure die-casting technology allows complex shapes and high-precision requirements to be realized. From mold development to die-casting to fine machining, every step is strictly controlled to ensure the quality of engine system die-casting parts.

For example, the cylinder head engine system die-casting parts we produce have exquisite internal structures and high-quality materials, which effectively improve the compression ratio and combustion efficiency of the engine. The carefully crafted die-cast parts of the intake pipe engine system significantly enhance the air intake effect through optimized airflow channel design. We will continue to be committed to innovating and optimizing the production process of engine system die castings to provide you with better quality and more reliable products to meet your continuous pursuit of engine performance.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

Why choose high-quality engine system die castings?

In the context of the continuous upgrading of the global automotive industry and power systems, engine system die castings have become one of the core components that affect the performance and durability of the whole vehicle. High-quality die castings can not only significantly improve the durability and working efficiency of the engine, but also reduce energy consumption, wear and maintenance costs. Ningbo Jinyao Machinery Co., Ltd. focuses on providing professional die casting and precision machining solutions for the automotive industry, hybrid and electric vehicle systems. With 16 years of industry experience, we are able to meet customers' strict requirements for high-performance engine components.

Our engine system die castings use high-quality alloy materials and advanced high-pressure die casting processes to ensure that the parts still have excellent stability and reliability under extreme conditions of high temperature and high pressure. For key parts such as automotive engines, powertrain components, motor housings, hybrid modules, etc., the accuracy of die castings directly determines the overall performance. The solutions provided by Jinyao Machinery strictly follow international standards from concept design, part design to mold manufacturing, and finally mass production and quality control to ensure the high consistency and high precision of each product.

With the increasing demand for lightweight and energy saving in the automotive industry, Jinyao Machinery not only provides die castings for traditional engine systems, but also focuses on the research and development of components for electric and hybrid energy systems. We can bring higher energy efficiency and market competitiveness to customers' products by optimizing die casting structure, improving strength and reducing weight. Our production workshop is equipped with fully automated production lines and intelligent testing equipment to ensure that the products have excellent surface finish, good mechanical properties and excellent corrosion resistance.

Choosing Ningbo Jinyao Machinery Co., Ltd. means that you will cooperate with a professional die casting supplier with rich international cooperation experience and a deep understanding of the needs of automotive power systems. Our die castings not only serve traditional automotive engine manufacturers, but also provide high-performance components for the powertrain of electric and hybrid vehicles. With years of accumulation, we have become a long-term partner of many well-known vehicle and power system manufacturers at home and abroad, providing them with one-stop services from design to mass production.

What are the unique advantages of our die castings?

Ningbo Jinyao Machinery Co., Ltd. has been committed to providing high-precision and high-reliability engine system die castings and powertrain components to global customers. We have independent mold development capabilities, advanced die-casting equipment and complete CNC machining centers, which can achieve precision production of complex structural parts while maintaining high efficiency. This full-process, customized solution gives us a significant advantage in the automotive parts supply chain.

Our die-casting parts use high-quality aluminum alloys, magnesium alloys and other lightweight materials, which significantly reduce the weight of parts while ensuring strength and toughness, helping customers achieve a dual improvement in vehicle lightweight design and fuel economy. We are particularly good at high-pressure die-casting (HPDC) and multi-cavity mold design, which can maintain product stability and dimensional accuracy in mass production. Jinyao Machinery's products undergo multiple rigorous inspection processes, including three-coordinate measurement (CMM), X-ray non-destructive testing, pressure testing and metallographic analysis to ensure the structural stability and surface quality of parts.

Today, as the automotive industry turns to new energy and hybrid systems, our die-casting solutions are not limited to traditional engine parts, but also cover electric vehicle motor housings, electronic control system components and thermal management modules. With 16 years of industry accumulation and continuous technological innovation, we can flexibly respond to the personalized needs of different customers in product research and development, and realize full-process technical support from drawing design to finished product delivery.

In addition to product advantages, Jinyao Machinery's service system is also trustworthy. We provide customers with engineering optimization suggestions to help them find potential problems in the early design stage, thereby saving development time and costs. Our team has rich experience in multinational projects and is familiar with international quality standards (such as IATF16949, ISO9001), ensuring that high-quality die-castings that meet standards are provided to global customers.

Our customer base is spread across major automotive manufacturing centers such as Europe, North America, and Southeast Asia, and long-term cooperative brands include well-known automobile manufacturers and powertrain manufacturers. Whether it is a large-volume order or a small-volume customized demand, Jinyao Machinery can provide customers with efficient and reliable supply experience with its strong flexible production capacity and rapid response mechanism.

Why working with us can make your business more valuable?

Choosing to cooperate with Ningbo Jinyao Machinery Co., Ltd., you can not only get high-quality engine system die-castings, but also experience integrated services from concept design to mass production delivery. As a professional die-casting and processing solution provider with 16 years of industry experience, Jinyao Machinery is deeply involved in the automotive industry, electric and hybrid energy systems, providing customers with customized die-casting and processing parts, covering powertrains, engine housings, thermal management components and a variety of complex structural parts.

We know that customers not only need high-quality parts, but also need fast delivery capabilities and efficient communication channels. With advanced automated die-casting production lines, CNC machining centers and quality inspection systems, we can shorten production cycles while ensuring high quality, helping customers seize market opportunities. We also have an experienced team of engineers who can participate in design optimization at the early stage of product development, provide customers with structural analysis, material selection and process improvement suggestions, and reduce overall development costs.

In the increasingly competitive global automotive market, supply chain stability and quality control are the key to success for enterprises. Jinyao Machinery not only has the ability to produce in large quantities, but also can provide flexible production solutions for small and medium batch orders, which gives us more advantages in dealing with market fluctuations and diversified customer needs. We have established a strict quality management system and passed a number of international certifications to ensure that every batch of die-casting parts shipped from the factory can meet customers' performance and safety standards.

Cooperating with Jinyao Machinery, you will get not only high-quality products, but also a long-term partner you can trust. Our goal is to create higher added value for customers through continuous innovation, quality service and efficient production. Whether you are a traditional car manufacturer or an innovator in the field of new energy and hybrid power, we can provide you with customized die-casting and precision machining solutions to make your business stand out in the global market.

English

English Español

Español Deutsch

Deutsch русский

русский Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings