Ningbo Jinyao Machinery Co., Ltd. is a China Engine cooling system die castings Suppliers and Engine cooling system die castings Foundry . And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Engine cooling system die castings Suppliers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

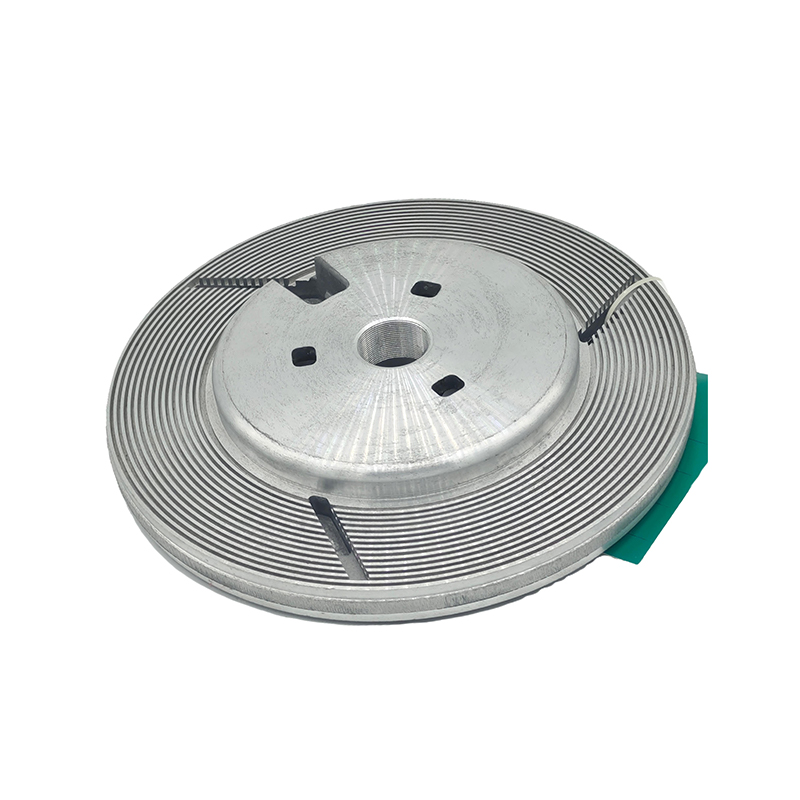

Engine cooling system die castings are key components in automobile engine cooling systems.

Its main purpose is to form various important components of the cooling system, such as water pump housing, radiator end cover, etc. The water pump housing die casting provides power support for the circulation of coolant to ensure that the coolant can flow in the engine; the radiator end cover helps to maintain the normal operation of the radiator.

In terms of function, die castings for engine cooling systems can withstand the pressure and temperature changes of coolant. They have good corrosion resistance and can effectively prevent coolant leakage, thereby ensuring the stable operation of the cooling system to maintain the normal operating temperature of the engine.

In terms of core performance, these die castings usually have high strength and hardness, can maintain structural stability in complex working environments, and are not easily deformed or damaged after long-term use. Their precise size and shape control can ensure close fit with other components of the cooling system, reduce friction and energy loss, and improve cooling efficiency.

In order to achieve these properties, advanced die-casting technology and precision mold manufacturing are used in the production process. For example, by optimizing mold design and die-casting parameters, the die-casting parts can have good surface quality and internal structure. In terms of materials, suitable aluminum alloy materials such as ADC12 and A380 are generally selected because aluminum alloys have the characteristics of low melting point, easy casting and high precision.

In addition, some die castings of engine cooling systems may have some special designs or treatments. For example, some water pump housing die castings may have optimized flow channel designs inside to improve the pumping efficiency of the coolant; and some radiator end cover die castings may have special treatments on sealing performance to enhance their leak-proof effect.

In short, engine cooling system die castings play a vital role in the normal operation and performance of automobile engines. Their quality and performance directly affect the efficiency of the cooling system and the reliability and durability of the engine.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

The key role of die castings in engine cooling systems

The main function of the engine cooling system is to ensure that the engine maintains a suitable temperature range during operation and prevent deformation, increased wear or performance degradation of parts due to overheating. In the cooling system, key components such as water pump housing, radiator end cover, thermostat housing, etc. are mostly manufactured using die casting technology to ensure high-precision molding and stability of complex structures. Die castings not only need to have excellent air tightness and corrosion resistance, but also must maintain stable performance for a long time under high temperature and high pressure environments, which places extremely high demands on manufacturing processes and quality control.

As a professional engine cooling system die casting manufacturer, Ningbo Jinyao Machinery Co., Ltd. continues to provide customers with high-precision, high-strength, high-quality products with strong production capacity and technical accumulation. The company is equipped with mold workshops, die casting workshops, CNC workshops, surface treatment workshops, polishing workshops, packaging workshops, raw material warehouses and three quality inspection rooms, which can realize integrated production from raw materials to finished products. This full-chain layout not only ensures the efficiency and flexibility of production, but also allows products to be strictly quality controlled in every manufacturing link.

Die castings in engine cooling systems, such as water pump housings, often require complex internal flow channels and high-strength shells. Traditional processing techniques are difficult to meet the dual requirements of lightweight and high performance at the same time. Die casting technology, especially aluminum alloy die casting technology, is the ideal solution to this problem. Ningbo Jinyao Machinery Co., Ltd. uses advanced die casting lean production lines and automatic deburring lines to not only produce parts with complex structures and high dimensional accuracy, but also improve the corrosion resistance and overall aesthetics of parts through surface treatment and passivation processes.

The company's annual precision casting production capacity of more than 100,000 tons ensures the stability and flexibility of batch supply, and provides reliable cooling system die casting solutions for many automobile manufacturers and engine parts suppliers. With a management system that strictly abides by industry standards and local regulations, Ningbo Jinyao Machinery Co., Ltd.'s products have obtained relevant certifications, which fully reflects the company's high sense of responsibility and continuous pursuit of quality, safety and environmental protection.

Application trend of aluminum alloy die casting in cooling system

The application of aluminum alloy die casting in automobile engine cooling system shows a rapid growth trend, because aluminum alloy has higher specific strength and lower weight than traditional materials such as steel. As the global automotive industry develops towards lightweight and energy-saving, aluminum alloy die castings are gradually replacing some steel castings to become the mainstream solution for engine cooling systems. Especially in new energy vehicles and hybrid models, the cooling system not only needs to dissipate heat for the engine, but also has to undertake the temperature control tasks of batteries and electronic control units, making the cooling system structure more complex and requiring higher performance and precision of parts.

Under this trend, Ningbo Jinyao Machinery Co., Ltd. relies on advanced die-casting production lines, automated processing equipment and lean manufacturing concepts to continuously explore and apply high-performance aluminum alloy materials, and actively introduce vacuum die-casting and semi-solid die-casting processes. Through these processes, enterprises can produce die-castings with fewer pores and higher density, effectively improving the mechanical properties and thermal conductivity of parts. The company has CNC workshops, cleaning lines and passivation lines, so that the aluminum alloy cooling system parts maintain excellent quality in the subsequent processing and surface treatment stages, meeting the use requirements under complex working conditions.

Aluminum alloy materials have excellent thermal conductivity, which means that during the operation of the cooling system, the aluminum alloy shell can transfer the heat generated by the engine to the coolant more quickly, improve the heat dissipation efficiency, and extend the service life of the engine. Ningbo Jinyao Machinery Co., Ltd. takes advantage of its annual production capacity of more than 100,000 tons to not only meet the production needs of large quantities of aluminum alloy cooling system die castings, but also provide customized solutions according to the design requirements of different projects of customers.

The company strictly implements the production and testing links in accordance with the high standards of the industry. The three quality inspection rooms and advanced testing equipment can realize multi-dimensional performance inspection, including air tightness testing, dimensional measurement and corrosion resistance testing. Through these quality control measures, the company ensures that each aluminum alloy die casting has stable quality and reliable performance before delivery, providing customers with higher safety and confidence in use.

Combination of intelligent manufacturing and quality control

With the continuous upgrading of the automotive industry and the rise of the global wave of intelligent manufacturing, the production of die-casting parts for engine cooling systems not only requires high precision and high efficiency, but also requires the use of digital and intelligent means to achieve full-process quality control. The core advantage of intelligent manufacturing lies in the deep combination of automated equipment, real-time data monitoring and process optimization to form an efficient, stable and traceable production chain.

Ningbo Jinyao Machinery Co., Ltd. follows this trend and fully introduces automation and information systems to create a high-level intelligent manufacturing system. The company has advanced equipment such as die-casting lean production lines, automatic deburring lines, finishing center lines, cleaning lines and passivation lines. These equipment are combined with digital management systems to enable real-time monitoring and parameter control of the entire production process. For example, in the die-casting process, the temperature, pressure and pouring speed of each mold can be tracked through digital records to ensure the consistency and stability of parts.

The company attaches great importance to quality control and regards "quality first" as one of its core competitiveness. By setting up three independent quality inspection rooms, equipped with advanced non-destructive testing equipment (such as X-ray inspection, CT scanning) and multi-dimensional testing methods, the company can quickly identify and correct potential problems such as pores and shrinkage in mass production. With the help of an intelligent data analysis platform, Ningbo Jinyao Machinery Co., Ltd. can achieve quality traceability throughout the entire process to ensure that each batch of products meets the high standards of customers.

The company also strictly abides by industry regulations and environmental protection standards, adopts green and environmentally friendly production processes, and ensures that while improving efficiency and quality, it also fulfills its commitment to environmental protection and social responsibility. The company's certification system not only reflects its emphasis on quality and safety, but also provides confidence and assurance for cooperation with global customers. With the combination of intelligent manufacturing and high quality standards, Ningbo Jinyao Machinery Co., Ltd. is gradually becoming an industry benchmark in the field of Engine cooling system die castings.

English

English Español

Español Deutsch

Deutsch русский

русский Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings