Ningbo Jinyao Machinery Co., Ltd. is a China Die Casting Motor Housing And End Shield Manufacturers and Motor Housing Die Castings Suppliers. And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

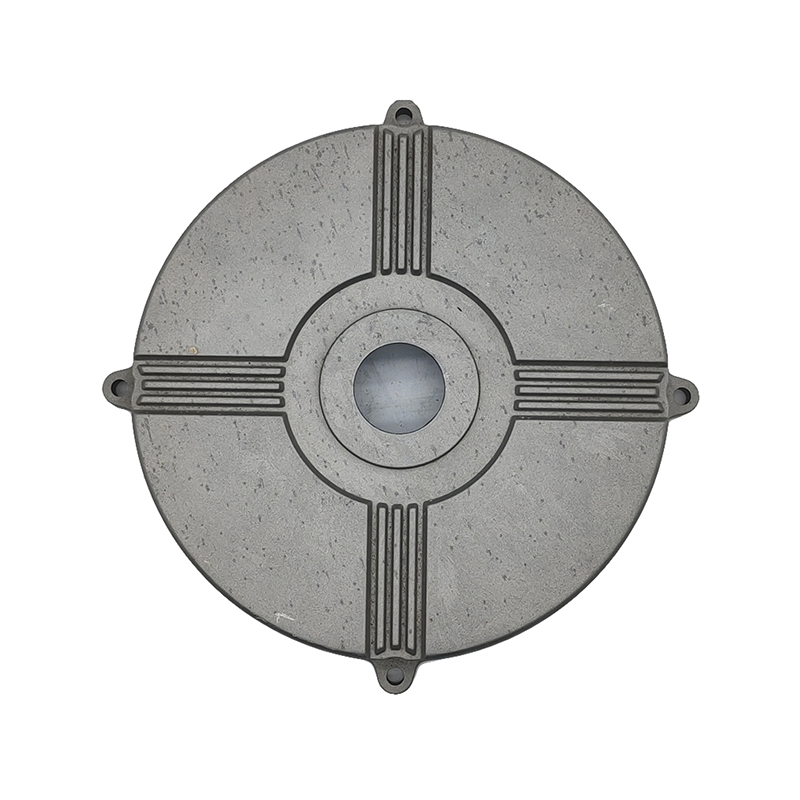

Motor housing die castings Manufacturers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

Motor housing die castings play a vital role in various industries.

These die-cast components are manufactured using the die-casting process and serve as protective enclosures for motors. They have several notable characteristics. First, they offer high precision. The die-casting process allows for dimensional and shape accuracy, meeting the strict assembly requirements of motor housings. In fields such as CNC machines and robotics, where high motor performance is crucial, these castings ensure smooth operation and precise control. Additionally, they provide high strength, typically made from aluminum alloys or other metals, effectively protecting the internal components of the motor and withstanding the stresses and vibrations during motor operation. Furthermore, they excel in heat dissipation. The thermal conductivity of the metal allows motor housing die castings to efficiently transfer heat generated inside the motor, ensuring it operates within a safe temperature range and extending its service life. Lastly, die casting is highly efficient, making it suitable for mass production, which lowers manufacturing costs by producing large quantities of motor housings quickly.

The manufacturing process begins with mold design and production. Based on the design requirements of the motor housing, precise molds are crafted, as their quality directly impacts the final die casting. Next is the melting and casting phase, where materials such as aluminum alloys are heated to a liquid state and injected into the die-casting machine’s chamber. The molten metal is then rapidly forced into the mold cavity using a high-pressure injection system to form the desired shape. Finally, once the casting has solidified and cooled, it is removed from the mold for post-processing, including deburring, shot blasting, and machining, to improve surface quality and dimensional accuracy.

Motor housing die castings are widely used across many sectors. In the industrial field, they are integral to motors used in machinery, fans, pumps, and various other industrial equipment, meeting the high demands for motor performance and reliability. In the automotive sector, they are required for components like engines, electric power steering systems, and electric vehicle drive motors. With the increasing focus on motor performance and lightweight materials, their use in the automotive industry is expanding. In the household appliance sector, motor housing die castings are critical for reducing noise and vibration in appliances such as air conditioners, washing machines, and refrigerators.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

English

English Español

Español Deutsch

Deutsch русский

русский

Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings