Ningbo Jinyao Machinery Co., Ltd. is a China Cylinder body die castings Suppliers and Cylinder body die castings Foundry . And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Cylinder body die castings Suppliers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

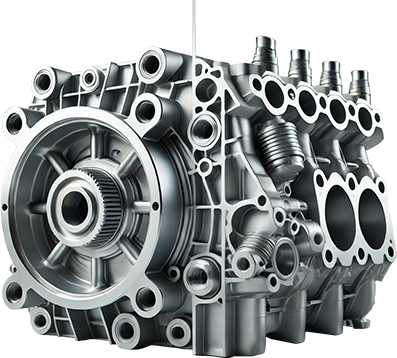

Cylinder body die castings are critical components of internal combustion engines, and their manufacturing quality significantly impacts engine performance, efficiency, and longevity. Typically made from aluminum alloy using high-pressure die casting (HPDC), cylinder body die castings offer lightweight construction, high strength, and heat dissipation, which meet the stringent requirements of modern high-performance engines. The high thermal conductivity of aluminum alloys enhances engine cooling, preventing overheating under high loads, while its corrosion resistance extends the service life of the cylinder body.

The high-pressure die-casting process ensures the dimensional accuracy and surface quality of the castings by injecting molten metal into precision molds at extremely high pressure, reducing internal defects such as porosity and shrinkage, and improving the density and mechanical properties of the castings. The cylinder body contains complex structures like cooling channels and oil passages, requiring exceptionally high precision in mold design and processing. Cylinder body die castings must meet stringent requirements for high strength, heat resistance, and wear resistance to endure the high pressure and temperature generated during engine operation. They must also maintain dimensional stability to ensure smooth piston movement and overall engine efficiency. Advanced non-destructive testing techniques, such as X-ray inspection, CT scanning, and ultrasonic testing, are employed during the manufacturing process to control key dimensions and geometric tolerances, ensuring assembly precision and mechanical performance.

Through precision manufacturing techniques, thoughtful design considerations, and rigorous quality control, cylinder body die castings are able to meet the high-performance and durability demands of modern internal combustion engines, ensuring engine stability and reliability under various operating conditions.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

What are the strength and durability of cylinder die castings?

The influence of material selection on the strength of cylinder die castings

The strength of cylinder die castings mainly depends on the materials used. Common materials include aluminum alloys, cast iron, etc. Among them, aluminum alloys are widely used in cylinder die castings due to their light weight and good processability. Aluminum alloy materials have good oxidation resistance and corrosion resistance. At the same time, compared with other metal materials, aluminum alloys have lower density, which can effectively reduce the weight of the cylinder, thereby improving the overall performance of mechanical equipment.

When selecting aluminum alloy materials, its alloy composition and hardness are key factors affecting the strength of die castings. For example, aluminum silicon alloy (A356) is often used as a material for cylinder die castings due to its good casting properties and high strength. In addition, suitable alloy ratios and appropriate heat treatment processes can effectively improve the strength and durability of the cylinder and prevent deformation or fracture under high loads.

The influence of production process on the strength of cylinder die castings

The strength of cylinder die castings depends not only on the selection of materials, but also on its production process. Modern die-casting technologies such as vacuum casting, pin extrusion and high-pressure spot cooling processes all play an important role in ensuring the strength of aluminum alloy die castings. The vacuum casting process can effectively reduce the generation of pores, improve the density of castings, and thus enhance their tensile strength and fatigue resistance.

The high-pressure spot cooling process adopted by Ningbo Jinyao Machinery Co., Ltd. reduces the internal stress of aluminum alloys by timely cooling the metal flow during the casting process, avoiding cracks and deformation problems caused by uneven cooling. This process can improve the internal structural quality of cylinder die castings, so that they can maintain high strength and stability under high temperature and high pressure environments.

Improvement of durability by design optimization of cylinder die castings

In addition to materials and processes, the design of cylinder die castings is also an important factor affecting their strength and durability. Reasonable design can effectively disperse and transfer external loads, reduce the problem of local stress concentration, and thus improve overall strength. In the design process of cylinder die castings, it is necessary to consider the complexity of the working environment, such as working performance under conditions of high temperature, high pressure and vibration.

Ningbo Jinyao Machinery Co., Ltd. uses advanced CAE (computer-aided engineering) analysis technology when designing cylinder die castings to optimize the structure and thickness of the cylinder to ensure better durability and reliability when subjected to pressure and high temperature. In addition, the internal structure of the casting, such as the layout of the ribs and support structures, must be taken into account during the design process to avoid material fatigue due to excessive concentrated stress.

The effect of heat treatment process on durability of cylinder die castings

The heat treatment process is one of the important means to improve the durability of cylinder die castings. Through proper heat treatment, the internal grain structure of aluminum alloys can be changed, and the hardness and corrosion resistance of the material can be enhanced. Common heat treatment methods include aging treatment, solution treatment, etc.

In the production process of Ningbo Jinyao Machinery Co., Ltd., all cylinder die castings undergo a strict heat treatment process to ensure their long-term stability in actual use. For example, aging treatment can improve the strength and hardness of the cylinder, thereby improving its wear resistance and fatigue resistance. In some special application areas, different heat treatment processes can also be used for customized treatment for specific working environments to meet the needs of different customers.

The influence of the use environment of cylinder die castings on durability

The durability of cylinder die castings is not only affected by materials, processes and designs, but also closely related to their actual use environment. Cylinder die castings used under extreme conditions such as high temperature, high pressure, and vibration need to have stronger corrosion resistance and wear resistance. For example, in automobile engines or construction machinery, the cylinder is often in an extreme working environment and needs to withstand constantly changing loads and temperatures. Therefore, the durability of cylinder die castings often determines the service life of the entire vehicle or equipment.

In the production practice of Ningbo Jinyao Machinery Co., Ltd., the company has developed cylinder die castings that adapt to different working conditions in response to the needs of different application fields. These die castings not only take into account the durability under high temperature and high pressure environments in design, but also carry out targeted optimization in material selection and process, thereby improving the performance of die castings in harsh environments.

Quality control of cylinder die castings

In order to ensure the strength and durability of cylinder die castings, a strict quality control system is indispensable. At Ningbo Jinyao Machinery Co., Ltd., all cylinder die-castings undergo multiple rigorous inspection processes, including dimensional inspection, non-destructive testing, strength testing, etc. Through high-precision inspection equipment and strict quality standards, we ensure that each die-casting meets customer requirements.

In the actual production process, all cylinder die-castings will undergo detailed appearance inspection and functional testing to ensure that there are no defects before delivery. At the same time, the company will also conduct technical training regularly to enhance employees' quality awareness and operating skills, and further ensure the quality of each cylinder die-casting produced.

What are the production processes and application areas of cylinder die castings?

Production process of cylinder die castings

The production process of cylinder die castings involves multiple steps, from material selection to finished product inspection, to ensure its final performance. Ningbo Jinyao Machinery Co., Ltd., as a professional manufacturer of aluminum alloy precision castings, adopts advanced process technology to ensure the high quality and high performance of the products.

Material selection: The material selection of cylinder die castings directly affects its strength, durability and application performance. Generally, aluminum alloy is the main material for manufacturing cylinder die castings, which is widely used in industrial applications due to its light weight, high strength and good thermal conductivity. According to different application requirements, aluminum alloys with different compositions, such as aluminum silicon alloy, aluminum copper alloy, etc., can be selected to meet the performance requirements under different working conditions.

Die casting process: The production of cylinder die castings usually adopts high-pressure die casting process. This process injects molten metal into a pre-prepared mold and uses high pressure to quickly fill the entire mold cavity. The high-pressure die casting process can ensure the precision and strength of aluminum alloy materials, making the die casting surface smooth, accurate in size, and free of pores, reducing the workload of subsequent processing.

Ningbo Jinyao Machinery Co., Ltd. uses high-pressure spot cooling technology, which can control the solidification rate of aluminum alloy during the casting process, reduce defects such as pores and cold shuts inside the casting, and ensure the internal quality of the cylinder die casting.

Vacuum casting process: The vacuum casting process introduces a vacuum environment during the die casting process, which helps to remove bubbles and impurities inside the casting by reducing the gas pressure, and improves the density and strength of the casting. The vacuum casting process is usually used for the production of die castings that require high strength and low pores, which helps to ensure that the cylinder die casting has stronger pressure resistance during operation.

Pin extrusion process: The pin extrusion process is another common aluminum alloy die casting process, which is mainly used to manufacture die castings with complex shapes and precision structures. Through this process, the various parts of the cylinder die casting can be made more uniform and deformation caused by uneven stress can be avoided.

Post-processing process: After the cylinder die casting is produced, it needs to go through a series of post-processing processes, including cleaning, polishing, heat treatment and other steps. These processes can further improve the surface quality and mechanical properties of the die casting and ensure that it can adapt to complex working environments.

Application fields of cylinder die castings

Cylinder die castings are widely used in various types of mechanical equipment, especially under harsh working conditions such as high load and high temperature, the excellent performance of cylinder die castings is particularly important. The following are the applications of cylinder die castings in different fields.

Automobile industry: In the automotive industry, cylinder die castings, as an important component of key components such as engines and transmissions, play an important role in carrying and transmitting power. Cylinder die castings are usually required to have good strength, heat resistance and fatigue resistance to ensure the stable operation of the engine under high temperature and high pressure. Especially in the cylinder part of the automobile engine, aluminum alloy die castings not only provide sufficient strength, but also effectively reduce the weight of the whole vehicle, improve fuel efficiency and power performance.

Cylinder die castings of Ningbo Jinyao Machinery Co., Ltd. provide high-quality parts for many automobile manufacturers, including some of the world's top 500 companies. Through precision casting technology, ensure that the cylinder maintains stable working performance in long-term use.

Engineering machinery: In engineering machinery such as excavators, loaders and other equipment, cylinder die castings bear important structural functions. In these devices, cylinder die castings need to have high impact resistance and wear resistance to adapt to harsh working conditions. High-pressure casting process can provide high strength and good wear resistance, ensuring that cylinder die castings can work continuously and stably under heavy load and high-pressure working environment.

Train industry: In the train industry, cylinder die castings are widely used in parts such as carriages, engines and chassis. The cylinder die castings of trains are required to have high corrosion resistance, shock resistance and fatigue resistance to cope with the challenges brought by long-term operation. Through precise casting process and high-quality materials, cylinder die castings can maintain good performance under extreme conditions such as high temperature, humidity and vibration.

Communication equipment: Cylinder die castings are widely used in communication equipment, especially in base station equipment and housing components. Since communication equipment is often exposed to outdoor environments, cylinder die castings need to have strong corrosion resistance and weather resistance. The good thermal conductivity and corrosion resistance of aluminum alloy make it an ideal material for manufacturing communication equipment housings.

Outboard engines: Outboard engines are an important part of water sports and boats, and cylinder die castings play a key role in them. Since outboard engines are used for a long time in waters with high humidity and high salinity, the cylinder body needs to have strong corrosion resistance and high temperature resistance. High-quality aluminum alloy cylinders can effectively cope with the harsh conditions in the water environment and extend the service life.

Lighting equipment: In the lighting industry, cylinder die castings are mainly used for the housing of lamps. Since lamps need to maintain high-intensity operation for a long time, cylinder die castings must have good thermal conductivity while ensuring strength to prevent overheating. In addition, lamps often need to be exposed to outdoor environments, so the corrosion resistance and weather resistance of cylinder die castings have also become important performance indicators.

As the core component of a variety of mechanical equipment, the production process and application field of cylinder die castings are closely related. Through advanced technologies such as high-pressure casting and vacuum casting, Ningbo Jinyao Machinery Co., Ltd. provides high-quality cylinder die castings for various industries, ensuring the reliability and durability of these equipment in extreme environments such as high temperature, high pressure, and heavy load. Whether in the fields of automobiles, construction machinery, trains, communication equipment or lamps, cylinder die-castings play an indispensable role. They not only meet customers' strict requirements on product performance, but also provide guarantee for the long-term stable operation of equipment.

English

English Español

Español Deutsch

Deutsch русский

русский Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings