Ningbo Jinyao Machinery Co., Ltd. is a China Radar housing die castings Suppliers and Radar housing die castings Foundry . And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Radar housing die castings Suppliers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

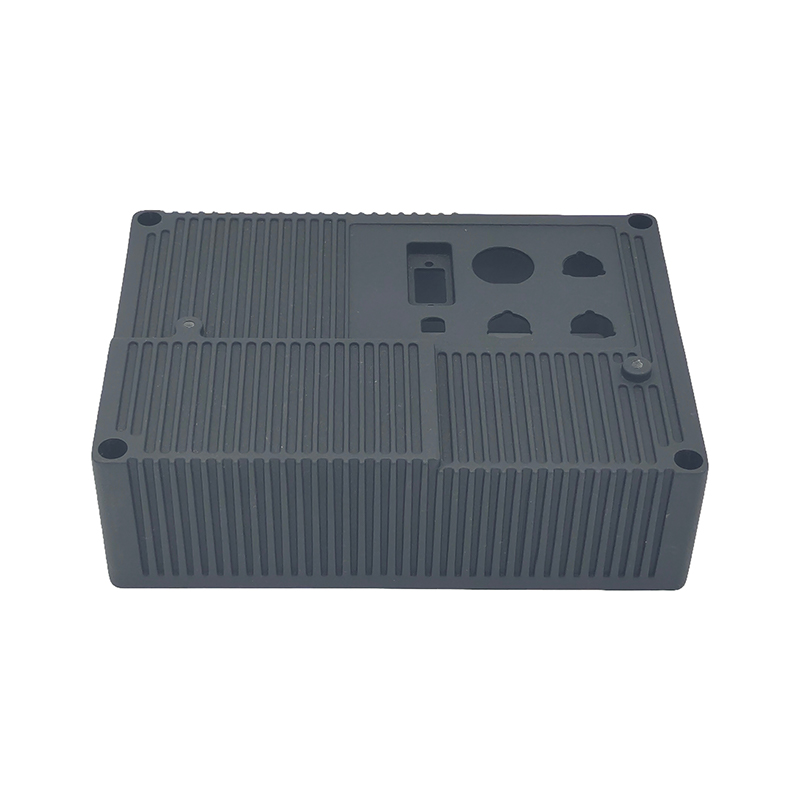

Radar housing die castings play a crucial role in radar equipment.

Radar housing die castings are typically manufactured using die-casting processes and possess several key characteristics. Firstly, their structure is often complex, featuring various recesses, holes, slots, and reinforcing ribs to meet the installation and protection needs of internal electronic components, while also adapting to different working environments and installation methods. Secondly, they require high dimensional precision, as accurate dimensions ensure the proper installation of internal electronic components, safeguarding the radar's normal operation and avoiding installation difficulties or signal transmission issues due to dimensional deviations.

In terms of material selection, materials with good mechanical properties, thermal conductivity, and corrosion resistance, such as aluminum alloys, are generally used. Aluminum alloys not only have a relatively low density, contributing to the lightweight design that facilitates the installation and transportation of the radar, but they also provide heat dissipation while meeting strength requirements. This ensures that the heat generated during radar operation can be effectively dissipated, maintaining the internal temperature within a normal range.

Additionally, radar housing die castings need to possess certain electromagnetic shielding capabilities to reduce interference from external electromagnetic signals on the radar's internal electronic components. This may be achieved through special material treatments or structural designs, such as applying conductive coatings on the housing surface or using conductive materials at seams to create a continuous conductive body, thereby effectively shielding electromagnetic waves.

In summary, radar housing die castings, with their complex structural design, high dimensional accuracy, material properties, and electromagnetic shielding function, provide a solid foundation for the stable operation and reliable performance of radar equipment.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

Overview of Radar Housing Die Castings

Radar housing die castings play a vital role in radar equipment, especially in ensuring equipment stability and efficient performance. Ningbo Jinyao Machinery Co., Ltd.'s leading advantage in aluminum alloy precision casting gives it a significant technical advantage in the production of radar housing die castings. Radar housings are usually manufactured through high-pressure casting processes and have several key features. First, the structure of the radar housing is usually complex, and the design includes multiple grooves, holes, notches and reinforcement ribs to meet the installation and protection needs of internal electronic components, while adapting to different working environments and installation methods. The company uses advanced vacuum casting, needle extrusion and high-pressure point cooling processes to ensure that each casting has high precision and stability in complex structures, avoiding installation difficulties or signal transmission problems caused by dimensional deviations.

Radar housing die castings require extremely high dimensional accuracy to ensure that internal electronic components can be installed correctly and ensure the normal operation of radar equipment. Ningbo Jinyao Machinery uses its precision casting technology to strictly control the size and shape of each production link to ensure that the product meets high precision requirements, thereby ensuring the stability and accuracy of the radar system.

In terms of material selection, Ningbo Jinyao Machinery selects aluminum alloy materials with excellent mechanical properties, thermal conductivity and corrosion resistance. Aluminum alloy not only has low density, which helps the lightweight design of radar and is easy to install and transport, but also has excellent heat dissipation performance, which effectively meets the heat management needs of radar operation. In addition, the strength and corrosion resistance of aluminum alloy enable it to operate stably for a long time in various complex environments, ensuring the efficient operation of radar equipment.

Radar shell castings also need to have certain electromagnetic shielding capabilities to reduce the interference of external electromagnetic signals on the internal electronic components of the radar. Jinyao Machinery uses special material processing processes, such as coating the surface of the shell with a conductive coating, or using conductive materials at the joints to form a continuous conductor, thereby effectively shielding electromagnetic waves and ensuring the accuracy and stability of the radar.

By utilizing advanced aluminum alloy precision casting technology, strict quality control and innovative design solutions, Ningbo Jinyao Machinery not only provides strong structural support for radar shell castings, but also ensures its stable operation in various extreme environments, becoming a reliable partner of radar equipment manufacturers in many industries around the world.

Design requirements for radar shell castings

The design of radar shell castings involves many aspects to ensure that they can not only provide physical protection but also meet the functional requirements of radar equipment, especially in an environment of high precision, high stability and long-term operation. The following are several factors that need to be considered when designing radar shell castings:

Complex structural design: The structure of radar shell castings is usually complex, containing multiple cavities, channels and reinforcing ribs. These designs can not only improve the strength of the shell, but also optimize the internal space layout and provide a good support structure for the installation and protection of sensitive electronic components inside the radar. In addition, the complex design can also ensure the adaptability of the radar shell in different environments, such as high temperature, low temperature, humidity or vibration.

Dimensional accuracy requirements: The precision requirements of radar shell castings are very high, and accurate dimensions are crucial for the installation of internal electronic components. If the size of the shell deviates, the internal components of the radar may not be installed correctly, thus affecting the normal operation of the equipment. Dimensional accuracy is directly related to the performance of the equipment and the convenience of installation. Therefore, the dimensional tolerance of the casting must be strictly controlled during the production process to ensure that the housing matches other components perfectly.

Thermal management design: Radar equipment generates a lot of heat when working, especially in a high-load working environment. In order to avoid overheating of the equipment, resulting in damage to internal components or performance degradation, the radar housing casting must have good heat dissipation performance. Usually, structures such as heat sinks and heat dissipation holes are designed, through which the heat generated by the radar during operation is effectively dissipated to keep the internal temperature within a safe range. This not only helps to improve the stability of the radar, but also extends the service life of the equipment.

Electromagnetic shielding capability: The electronic components inside the radar equipment are very sensitive to external electromagnetic interference, and electromagnetic waves may affect the signal transmission of the radar and even cause equipment failure. Therefore, the radar housing casting needs to have a certain electromagnetic shielding capability. To achieve this function, manufacturers usually use conductive coatings, special seam designs, or use conductive materials to create a continuous conductor, thereby effectively reducing the interference of external electromagnetic waves and ensuring the accuracy and stability of the radar.

Material selection: In order to meet the strength, thermal conductivity and corrosion resistance requirements of radar housing die castings, aluminum alloy is usually used as the main material. Aluminum alloy not only has a low density, which is suitable for the lightweight requirements of radar equipment, but also has good thermal conductivity, which helps to effectively dissipate heat. In addition, aluminum alloy has strong corrosion resistance, which can ensure the long-term stability of the radar shell in various harsh environments.

Manufacturing process of radar shell castings

The manufacturing process of radar shell castings usually adopts high-pressure casting process to ensure that the castings meet high standards in strength, precision and surface quality. The following are the main manufacturing steps of radar shell castings:

Mold design and manufacturing: The first step of high-pressure casting is the design of the mold. The mold needs to be customized according to the complex structure and size requirements of the radar shell. Accurate mold design ensures that the casting can be produced in a predetermined shape and size while ensuring the quality and consistency of the casting.

Casting and cooling: In the high-pressure casting process, metal materials such as aluminum alloys are heated to a molten state and then injected into the mold by high pressure. High-pressure casting can ensure that the molten metal quickly fills every detail of the mold and maintains high precision and complex structure castings. After the casting is cooled in the mold, it is demolded and further processed to ensure its size and surface quality.

Surface treatment: In order to improve the corrosion resistance and aesthetics of the radar housing, the castings are usually surface treated, such as anodizing, electroplating or powder coating. Anodizing can not only enhance the corrosion resistance of aluminum alloys, but also improve the appearance of castings and increase their wear resistance; electroplating and powder coating can improve the protective performance of castings and extend their service life.

Quality inspection and precision machining: Strict quality control is required during the production process of radar housing die castings, including size inspection, appearance inspection, strength testing, etc. For some parts that require precise assembly, precision machining such as drilling and cutting is also required to ensure the accuracy and installation requirements of the castings.

Application fields of radar housing die castings

Radar housing die castings are widely used in many fields, especially in the fields of military, aviation, meteorology, traffic monitoring, etc. The following are several main application scenarios:

Military radar: Radar housing die castings are widely used in military radar equipment, which are usually used for tasks such as target detection, surveillance and missile control. Due to the extremely harsh working environment of military radars, the durability, heat dissipation and electromagnetic shielding capabilities of radar housing die castings are particularly important.

Weather radar: Weather radar is used to monitor weather conditions, and radar housing die castings provide key protection and thermal management functions in these devices. Weather radars are usually deployed in high temperature and high humidity environments, and the corrosion resistance and heat dissipation performance of the housing castings are critical to the stable operation of the equipment.

Traffic monitoring radar: In the field of traffic monitoring, radar housing die castings are used for equipment such as traffic speed measurement and vehicle speed monitoring. Since these devices need to be exposed to outdoor environments for a long time, the corrosion resistance and structural strength of the castings are key to ensuring the normal operation of the equipment.

Aviation radar: Aviation radar is used for tasks such as navigation and air traffic control, and radar housing die castings provide it with effective protection and heat dissipation. The working environment of aviation radar is relatively complex, and the lightweight design of castings also plays an important role in improving equipment performance.

English

English Español

Español Deutsch

Deutsch русский

русский Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings