Ningbo Jinyao Machinery Co., Ltd. is a China Base station housing die castings Suppliers and Base station housing die castings Foundry . And is an enterprise integrating industry and trade, dedicated to the production of precision castings of aluminum alloy materials and the design and manufacture of high-pressure die-casting molds. Adopting advanced vacuuming, pin extrusion, and high-pressure spot cooling processes, it is a large-scale professional production base for diversified casting in China. It integrates a precision casting factory and a mechanical processing plant, and can produce precision castings and various types of castings annually. More than 10,000 tons, mainly exported to Japan, Sweden and other countries. Among the customers we cooperate with are many OEM customers of trains, cars, forklifts, outboards, communication equipment, lamps, furniture parts and engineering machinery, including the world's top 500 companies. , has become an important supplier of their precision castings in China.

Base station housing die castings Suppliers

- Traditional automobile die castings

- New energy automobile die castings

- Communication housing die castings

- Electric scooter die castings

- Bicycle power motor die castings

- Motorcycle accessories die castings

- Motor housing die castings

- Engineering machinery die castings

- Lighting die castings

- Outboard motor die castings

- Furniture accessories die castings

- Grill accessories die casting

- Photovoltaic inverter die castings

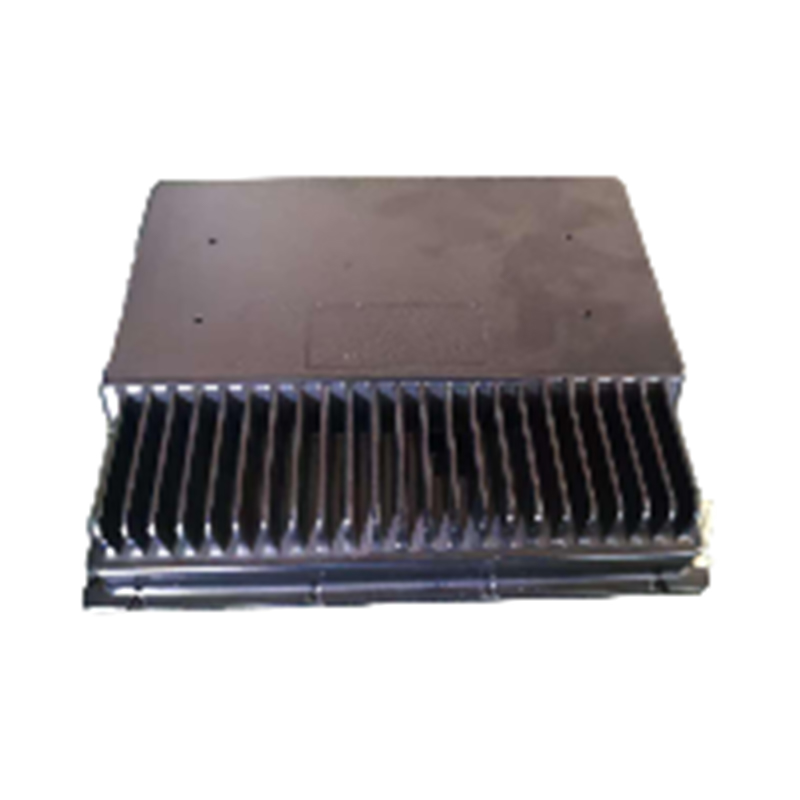

Base station housing die castings are high-precision components specifically designed for communication base stations, including heat sinks, power protection module housings, and interface protection covers. These components are primarily manufactured through high-pressure die-casting processes, which ensure that the housings possess structural strength and surface quality while achieving the precise molding of complex geometries.

Base station housing die castings are typically made from aluminum alloys, offering outstanding thermal conductivity and corrosion resistance, allowing them to operate reliably over long periods under various harsh environmental conditions. In terms of design, base station housings not only need to provide mechanical strength and protection but also must optimize thermal management structures, such as incorporating fins or ventilation openings, to ensure the long-term stable operation of the equipment. To further enhance durability and appearance quality, the housings often undergo surface treatments such as anodizing, electroplating, or powder coating.

Additionally, stringent quality control measures, including dimensional inspection, non-destructive testing, and environmental testing, ensure the high reliability of base station housings. These components are widely used in high-demand scenarios, such as 5G base stations and micro base stations, ensuring the safe operation of communication equipment.

-

What Are the Key Technical Challenges in Die Casting Thin-Walled Outboard Motor Housing Components?View More

In the competitive marine propulsion market, the demand for high-performance, lightweight engines has pushed the boundaries of Outboard Motor Die Castings. Specifically, the manufacturing of thin-walled housing components—with wall thicknesses typically below 2.0mm—represents the pinnacle of die-cas...

-

What Quality Standards Should You Look for in a Global Motorcycle Die Casting Supplier for 2026?View More

1. IATF 16949:2016 – The “Entry Ticket” to the Motorcycle Die Casting Industry When evaluating suppliers for Motorcycle Accessories Die Castings, ISO 9001 is merely the baseline; IATF 16949:2016 is the gold standard for international competitiveness. As a quality management system specifically for t...

-

Aluminum vs. Zinc: Which Alloy Is Best for High-Performance Grill Accessories Die Casting?View More

In the competitive market of outdoor cooking appliances, the durability and aesthetic appeal of hardware can make or break a brand’s reputation. When it comes to Grill Accessories Die Casting, manufacturers are primarily faced with a choice between two versatile metals: Aluminum and Zinc. Both alloy...

Overview of base station housing castings

Ningbo Jinyao Machinery Co., Ltd. has significant production advantages in the field of aluminum alloy precision casting, especially in the production and design of base station housing castings. Base station housing die castings are high-precision components designed for communication base stations, mainly including heat sinks, power protection module housings and interface protection covers. These housings are usually manufactured through high-pressure casting processes to ensure that the housings provide structural strength while also having good surface quality and accurate molding of complex geometric shapes. The company uses advanced process technologies such as vacuum casting, needle extrusion and high-pressure point cooling to ensure that each base station housing casting not only has excellent structural strength and surface quality, but also can accurately mold complex geometric structures. These housings are usually made of aluminum alloy materials. Due to their excellent thermal conductivity and corrosion resistance, they can operate stably for a long time in various harsh environments, ensuring the efficient operation of base station equipment.

Design requirements for base station housing castings

The design of base station housing die castings must consider multiple key factors to ensure that they can provide optimal protection and performance in complex environments. The following are several aspects that need to be focused on during the design of base station shell castings:

Mechanical strength and protection function: One of the main functions of base station shell castings is to protect sensitive electronic components inside the base station from external physical impact, dust, moisture and other environmental factors. In communication equipment, especially 5G base stations, the internal electronic components are extremely sensitive to the external environment, and any interference from external factors may cause equipment failure. Therefore, base station shell castings must have sufficient strength and durability to withstand various pressures and impacts in long-term use. At the same time, the base station shell must also have protective functions such as impact resistance, corrosion resistance, waterproof and dustproof. These functions can effectively protect the base station equipment from damage and ensure its long-term stable operation, especially when exposed to outdoor environments for a long time, it can still maintain the good performance of the equipment and extend its service life.

Thermal management design: Base station equipment generates a lot of heat during operation, especially in 5G base stations and high-power equipment, where heat dissipation is particularly critical. The heat dissipation requirements of the equipment directly affect the performance and stability of the equipment. If the heat dissipation is insufficient, it may cause the equipment to overheat, which in turn affects the working efficiency, shortens the service life and even causes failures. Therefore, base station shell castings usually optimize thermal management by designing structures such as heat sinks and heat dissipation holes. These heat dissipation designs can help heat quickly conduct and dissipate from the inside of the device to the outside, avoiding the negative impact of overheating on device performance. This carefully designed thermal management structure can ensure that base station equipment can maintain stable operation under high load and high temperature environments, extending the service life of the equipment.

Environmental adaptability: Base station equipment is usually deployed in complex outdoor environments, especially in changing geographical locations such as cities, mountains, deserts, and seaside. The equipment not only has to cope with extreme temperature differences, but may also face harsh environmental conditions such as high temperature, low temperature, humidity, and salt spray. Therefore, base station shell castings need to have extremely high corrosion resistance and waterproof and dustproof capabilities. This means that the castings must be able to effectively resist oxidation, corrosion, salt spray and moisture erosion, thereby ensuring the stable operation of base station equipment in these extreme environments. These environmental adaptability requirements ensure that the equipment can still provide communication services stably for a long time even under the most severe conditions.

Surface treatment and aesthetics: In order to further improve the corrosion resistance and aesthetics of base station shell castings, surface treatment processes such as anodizing, electroplating, and powder coating are usually used. Anodizing can not only enhance the corrosion resistance of castings, but also form a uniform protective film on the surface, improve the wear resistance and oxidation resistance of castings, and extend their service life; electroplating can provide castings with stronger corrosion resistance and good appearance, and enhance metal surface protection; powder coating can not only provide beautiful surface effects, but also enhance the UV resistance and chemical resistance of castings. These surface treatment processes can not only improve the corrosion resistance of castings, but also effectively improve the appearance quality, meeting the dual requirements of modern communication equipment for appearance and function.

Manufacturing process of base station shell castings

In the production process of base station shell castings, it is common to use high-pressure casting process. This process can ensure that the castings meet high standards in terms of precision, strength and surface quality. The specific manufacturing process is as follows:

Mold design and manufacturing: The first step of high-pressure casting is mold design. The design of the mold needs to take into account factors such as the complex structure of the casting, thermal management design, and dimensional tolerance. Good mold design can ensure the precision and quality of the casting.

Melting and casting: After melting metal materials such as aluminum alloys, they are injected into the mold under high pressure for casting. The high-pressure casting process ensures that the molten metal quickly fills every detail of the mold and maintains the high precision and complex shape of the casting.

Cooling and demolding: After the casting is cooled in the mold, the demolding operation is carried out. In order to prevent the casting from deformation or cracking during the cooling process, high-pressure point cooling technology is usually used to ensure uniform cooling of the casting by precisely controlling the cooling rate to avoid thermal stress and deformation.

Surface treatment: Base station housing die castings are usually surface treated to enhance their appearance and durability. Common surface treatment processes include anodizing, electroplating and powder coating, which not only improve the beauty of the castings, but also enhance their corrosion resistance and wear resistance.

Quality inspection and precision machining: Base station housing die castings require strict quality inspection, including dimensional inspection, appearance inspection, strength testing, etc. For some parts that require higher precision, subsequent precision machining such as drilling and cutting is also required.

Application areas of base station housing castings

Base station housing die castings not only provide the necessary physical protection, but also play a key role in optimizing heat dissipation, improving equipment stability and structural strength. Whether in high-load 5G base stations or in compact micro base stations and other communication equipment modules, base station housing castings have ensured the long-term stable operation of equipment with their excellent thermal management and reliability, and have become an indispensable and important part of modern communication infrastructure.

Base station housing die castings are widely used in various communication base station equipment. The following are several major application areas:

5G base station: With the popularization of 5G communication technology, the demand for high-performance housings for 5G base stations has surged. Base station housing die castings not only provide physical protection in 5G base stations, but also optimize heat dissipation design to ensure stable operation of equipment under high load.

Micro base stations: Micro base stations are often used for indoor coverage or communication coverage in small areas. Due to their small size, the design of base station housing castings needs to pay special attention to heat dissipation and structural strength to ensure the stable operation of the equipment.

Communication equipment module housing: In addition to base station housing die castings, base station housing castings are also commonly used in the housings of various communication equipment modules, including power protection modules, interface protection covers, etc. These castings not only provide structural protection, but also need to optimize thermal management to ensure the stable operation of the modules.

Other communication facilities: Base station housing die castings can also be used in other communication facilities, such as optical fiber accessories, satellite communication equipment, etc., to provide external protection and enhance the thermal management capabilities of the equipment.

English

English Español

Español Deutsch

Deutsch русский

русский Traditional automobile die castings

Traditional automobile die castings New energy automobile die castings

New energy automobile die castings Communication housing die castings

Communication housing die castings Electric scooter die castings

Electric scooter die castings Bicycle power motor die castings

Bicycle power motor die castings Motorcycle accessories die castings

Motorcycle accessories die castings Motor housing die castings

Motor housing die castings Engineering machinery die castings

Engineering machinery die castings Lighting die castings

Lighting die castings Outboard motor die castings

Outboard motor die castings Furniture accessories die castings

Furniture accessories die castings Grill accessories die casting

Grill accessories die casting Photovoltaic inverter die castings

Photovoltaic inverter die castings