Anodized aluminum die casting is a highly efficient manufacturing process that combines two distinct techniques—die casting and anodizing—into one to create parts that are both highly durable and visually appealing. This process is particularly beneficial for industries that require components with specific mechanical and aesthetic properties, such as automotive, aerospace, electronics, and consumer goods.

What is Die Casting?

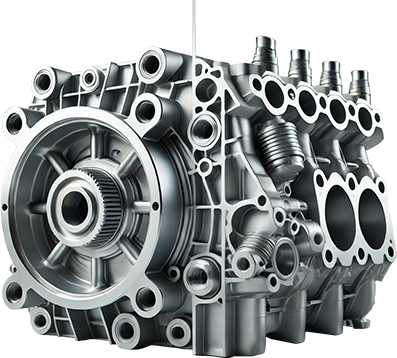

Die casting is a well-established manufacturing process used to produce precise and intricate metal parts. The key feature of die casting is that molten metal is injected into a mold (or die) under high pressure, which then cools and solidifies into a specific shape. The molds are typically made of steel and can withstand the pressure and temperature conditions during production. This method is known for its ability to create highly accurate parts with smooth surfaces, making it ideal for large-scale production runs.

The die casting process involves several key steps:

- Preparing the Mold: The mold is made from two steel halves that form the cavity into which the molten metal will be injected.

- Melting the Metal: Aluminum is melted in a furnace, and the molten aluminum is injected into the mold cavity under high pressure.

- Cooling and Ejection: Once the aluminum has filled the mold, it is allowed to cool and solidify. Afterward, the mold is opened, and the part is ejected.

The result is a highly precise and consistent part with minimal waste, which makes die casting an efficient choice for manufacturing complex components. One of the main advantages of die casting is the ability to produce parts with intricate details, making it suitable for industries that require high-performance components.

What is Anodizing?

Anodizing is an electrochemical process used to enhance the surface properties of aluminum. The goal of anodizing is to increase the thickness of the aluminum’s natural oxide layer, which provides a host of benefits such as improved corrosion resistance, increased surface hardness, and better paint adhesion. In anodizing, the aluminum part is immersed in an electrolyte bath (typically sulfuric acid) and subjected to an electric current, which causes the oxide layer to form on the surface of the aluminum.

The anodizing process can also be used to dye aluminum, allowing for a wide range of color options. The result is a part that not only performs better in harsh environments but also looks more attractive and can be customized for specific design requirements.

Anodizing involves several steps:

- Preparation: The aluminum part is thoroughly cleaned to remove any surface contaminants.

- Electrolytic Process: The part is immersed in an electrolyte bath and subjected to an electric current, causing the oxide layer to form on the surface.

- Sealing: After anodizing, the part is sealed to prevent further oxidation and improve its durability. The sealed surface is also more resistant to dirt and scratches.

By adding a protective and aesthetically pleasing oxide layer to the aluminum, anodizing enhances the material’s natural properties, making it a versatile choice for various applications.

How Does Anodized Aluminum Die Casting Work Together?

The combination of die casting and anodizing creates a powerful synergy that results in a part that is both strong and resistant to wear. Here’s how these two processes work together:

Step 1: Die Casting

The process begins with die casting, where molten aluminum is injected into a mold under high pressure. This produces a part with precise dimensions and high structural integrity. The die casting process can accommodate complex geometries and fine details, which is essential for applications that require intricate components.

After the aluminum has cooled and solidified, the die-cast part is removed from the mold. At this stage, the part may have a smooth surface but lacks the enhanced durability and aesthetic qualities needed for high-performance applications.

Step 2: Anodizing

Once the die-cast aluminum part has cooled, it is ready for anodizing. The part is subjected to an electrolytic process that increases the thickness of the oxide layer on its surface. This layer provides several advantages, such as:

- Corrosion Resistance: The anodized surface is much more resistant to corrosion compared to untreated aluminum. This makes anodized aluminum particularly useful in industries that deal with outdoor or harsh environments.

- Improved Surface Hardness: The anodized layer is harder than the base aluminum, making it more resistant to scratches and wear. This is essential for parts exposed to mechanical stress.

- Aesthetic Finish: The anodizing process allows for various color finishes, making it an excellent choice for products that require both functional and aesthetic properties.

Step 3: Benefits of the Combination

When die casting and anodizing are combined, the result is a component that is not only structurally sound but also more durable, corrosion-resistant, and visually appealing. The anodized aluminum die casting process is particularly popular in industries like automotive, aerospace, electronics, and consumer goods.

Some of the key benefits of anodized aluminum die casting include:

- Corrosion Resistance: Anodized aluminum is highly resistant to rust and degradation, making it ideal for parts exposed to moisture, chemicals, and other corrosive elements.

- Surface Durability: The anodized layer adds extra protection against physical wear and tear, which is vital for parts that experience regular friction or impact.

- Lightweight: Aluminum is known for being lightweight yet strong, which makes anodized aluminum die casting an excellent choice for applications that require both strength and reduced weight.

- Aesthetic Appeal: The anodizing process can provide a smooth, matte, or glossy finish, and it can also be dyed in a variety of colors, offering greater design flexibility for consumer-facing products.

Common Applications of Anodized Aluminum Die Casting

Anodized aluminum die casting is widely used in a variety of industries due to its durability, corrosion resistance, and aesthetic appeal. Some of the most common applications include:

- Automotive Industry: Anodized aluminum die casting is used for components like engine parts, trim pieces, and structural elements in vehicles. These parts require strength, corrosion resistance, and a high-quality finish.

- Aerospace: The aerospace industry uses anodized aluminum die casting for lightweight, durable, and corrosion-resistant components that must meet strict safety and performance standards.

- Electronics: In the electronics industry, anodized aluminum die casting is used for enclosures and housings for devices like smartphones, laptops, and power tools. These parts benefit from the protective properties of anodized aluminum while also providing an attractive finish.

- Consumer Goods: Anodized aluminum die casting is used in products such as outdoor furniture, sporting equipment, and kitchen appliances. The anodized finish provides both functional and aesthetic benefits, making it ideal for consumer-facing products.

Comparison of Anodized vs. Non-Anodized Aluminum Die Casting

| Property | Anodized Aluminum Die Casting | Non-Anodized Aluminum Die Casting |

|---|---|---|

| Corrosion Resistance | Excellent | Moderate to Low |

| Surface Hardness | High | Low |

| Aesthetic Finish | Customizable Colors and Gloss | Natural Aluminum Finish |

| Durability | Very High | Moderate |

| Application Areas | Automotive, Aerospace, Electronics | General Manufacturing |

Why Choose Anodized Aluminum Die Casting?

Anodized aluminum die casting offers the best of both worlds—strong, precise parts combined with enhanced durability and an attractive finish. Companies like Ningbo Jinyao Machinery Co., Ltd., which specialize in die casting, recognize the importance of providing customers with high-quality components that meet both functional and aesthetic requirements. With the increasing demand for products that perform well and look great, anodized aluminum die casting is becoming the preferred choice for a wide range of industries.

English

English Español

Español Deutsch

Deutsch русский

русский