1. Introduction

Amidst the global automotive industry's challenges of energy conservation, emission reduction, and sustainable development, lightweighting vehicles has become an inevitable development path. While traditional steel offers high strength, its excessive weight restricts fuel economy and the range of new energy vehicles. In contrast, aluminum alloy, with its light weight, high strength, and corrosion resistance, has gradually become an ideal material for automotive manufacturing.

The die-casting process rapidly fills molds with molten aluminum alloy under high pressure, forming complex components in a single step. This process offers the advantages of high precision, high efficiency, and low cost. Combining aluminum alloy with the die-casting process not only significantly improves vehicle performance but also meets the demands of large-scale production, helping the automotive industry achieve lightweighting and green manufacturing goals.

2. Advantages of Aluminum Alloy Die-Casting

Lightweight Performance

Aluminum has a density approximately one-third that of steel. Using aluminum alloy die-casting can significantly reduce vehicle weight. For fuel-powered vehicles, every 10% weight reduction reduces fuel consumption by 6%-8%. For electric vehicles, lightweighting directly impacts battery range. Excellent Mechanical Properties

Aluminum alloys possess excellent strength and toughness. Optimized die-casting processes enable them to meet the stringent safety and durability requirements of automotive components. Furthermore, aluminum alloys offer superior corrosion resistance to steel, helping to extend the life of vehicles.

High Forming Efficiency

The die-casting process enables the formation of complex shaped parts in a single step, significantly reducing subsequent machining steps. This not only shortens production cycles but also ensures dimensional accuracy and surface quality.

Cost Control

Although aluminum alloy raw material prices are higher than steel, the die-casting process reduces process and processing costs, optimizing overall manufacturing costs. Aluminum alloy die-casting exhibits significant economic advantages, particularly in high-volume production.

3. Applications of Aluminum Alloy Die-Casting in Automotive Applications

Powertrain

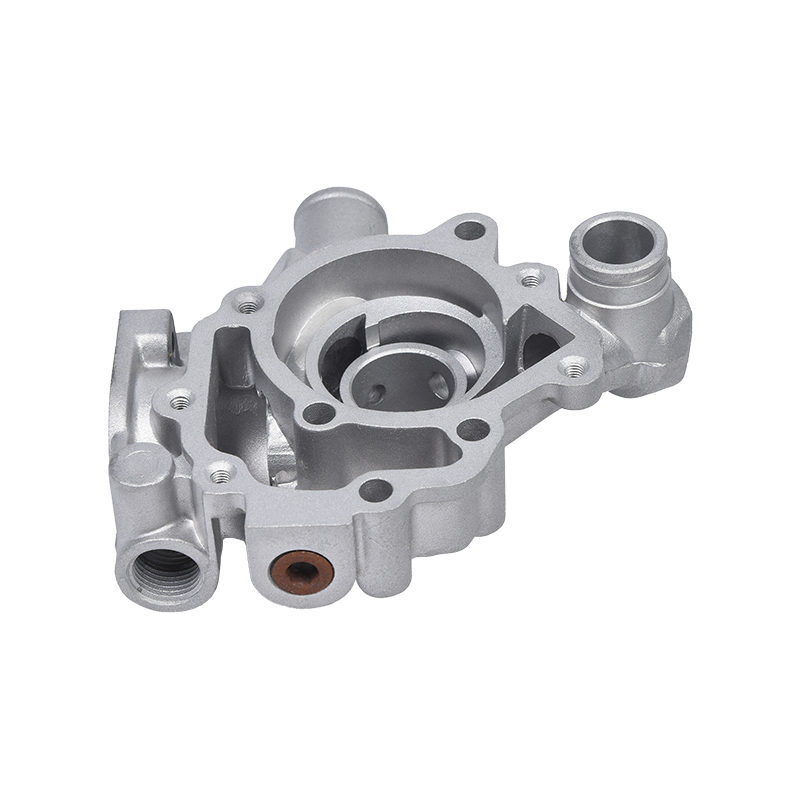

Common aluminum alloy die-castings, such as engine blocks, cylinder heads, and intake manifolds, ensure strength while reducing weight.

Transmission housings and clutch housings are manufactured with high precision through aluminum alloy die-casting, improving power transmission efficiency.

Chassis and Structural Parts

Suspension system brackets, control arms, and steering system components are increasingly adopting aluminum alloys, reducing weight while improving handling stability. Some load-bearing components are also beginning to be manufactured using high-strength aluminum alloy die-casting, replacing traditional steel.

Body and Interior

Die-casting offers significant advantages for parts such as door hinges, instrument panels, and seat frames due to their complex shapes.

The use of aluminum alloys further enhances interior comfort and durability.

New Energy Vehicle Components

Aluminum alloy die-casting is widely used for core components such as motor housings, battery trays, and inverter housings.

Battery trays, in particular, require extremely high strength, corrosion resistance, and heat dissipation, making aluminum alloy an ideal choice.

4. Technical Challenges and Solutions

Common Defects

Common problems with aluminum alloy die-casting include porosity, shrinkage, thermal cracking, and deformation. These defects not only affect the mechanical properties of the part but can also pose safety risks during use.

Process Optimization

High-Pressure Die Casting: High-speed and high-pressure filling improves density and reduces porosity defects.

Vacuum Die Casting: Vacuum is applied during the die-casting process to reduce air entrapment and enhance part strength.

Semi-Solid Die Casting: Semi-Solid Metal Slurry is used to form the part, minimizing shrinkage and deformation and improving precision. Material Innovation

As automotive component performance requirements continue to increase, new high-strength and toughness aluminum alloys are emerging. For example, high-silicon aluminum alloys are used for highly wear-resistant parts, while high-strength aluminum alloys are used for load-bearing components.

5. Future Development Trends

New Energy Vehicle Drive

Electric vehicles have an increasingly urgent need for lightweighting and heat dissipation. Lightweighting of key components such as battery trays and motor housings is directly related to battery life and safety, and the demand for aluminum alloy die-casting will continue to grow.

Intelligent Manufacturing Integration

Die-casting production is moving towards automation and digitalization. Sensors and data acquisition systems enable real-time monitoring of parameters such as temperature, pressure, and filling speed, enabling process optimization and quality traceability.

Green Manufacturing

Aluminum alloys have extremely high recycling value. Establishing a recycling system can reduce carbon emissions and align with the automotive industry's sustainable development strategy. Low-energy, environmentally friendly die-casting processes will also be a research and development focus in the future.

English

English Español

Español Deutsch

Deutsch русский

русский