Application of High-Precision Die Casting Technology in Bicycle Power Motors

Introduction

With the rapid growth of the global electric bicycle market, the power motor, as the core component, directly determines the efficiency and lifespan of the whole vehicle. Traditional manufacturing processes have certain limitations in meeting requirements such as lightweight design, heat dissipation, and high strength. High-precision die casting technology provides a new solution for motor manufacturing.

Overview of High-Precision Die Casting Technology

Definition and Characteristics of High-Precision Die Casting

High-precision die casting is a manufacturing process in which molten metal is injected into a steel mold under high pressure and rapidly cooled to form a stable structure. Compared with conventional die casting, it offers significant advantages in dimensional accuracy, surface quality, and mechanical properties.

Comparison with Traditional Processes

- Conventional die casting: Fast molding speed but lower accuracy and surface quality, requiring more post-processing.

- High-precision die casting: Smaller dimensional tolerance, better consistency, and reduced secondary machining costs.

Commonly Used Materials

- Aluminum alloys: Lightweight, high thermal conductivity, widely used in motor housings.

- Magnesium alloys: Even lower density, suitable for high-end bicycles seeking extreme lightweight design.

- Zinc alloys: Applied to smaller components requiring high strength and wear resistance.

Structure and Requirements of Bicycle Power Motors

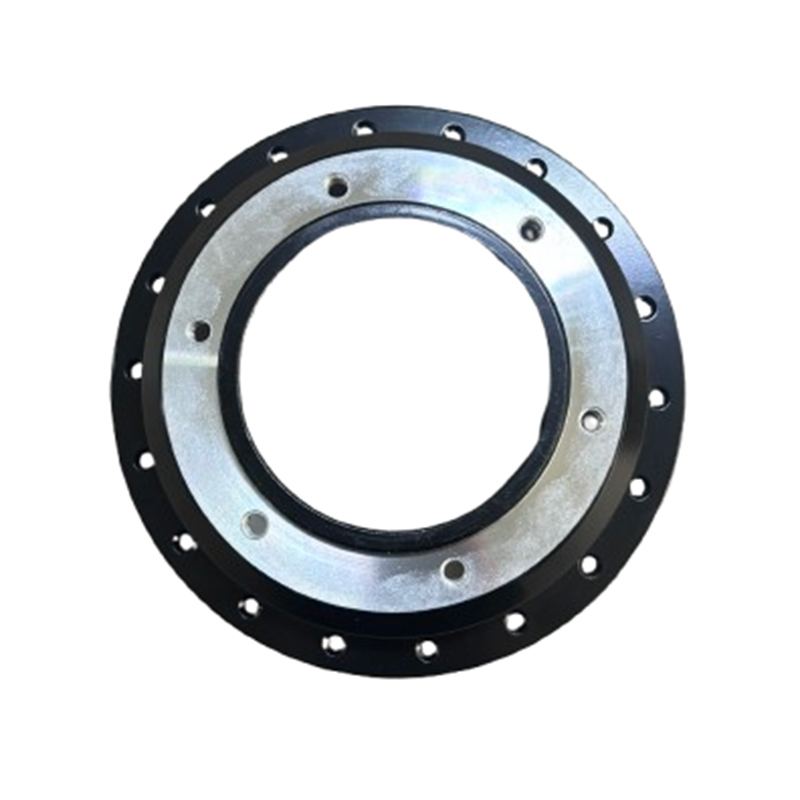

Role of Motor Housing and Brackets

The motor housing not only protects internal components but also plays a crucial role in heat dissipation and load-bearing. Brackets ensure stable motor installation.

Performance Requirements

- Lightweight: Reduce overall weight and increase range.

- Heat dissipation: Maintain stable temperature under high power operation.

- Strength and durability: Resist long-term vibration and load stress.

- Assembly precision: The rotor-stator air gap requires extremely high accuracy.

Application of High-Precision Die Casting in Motor Manufacturing

Motor Housing Die Casting Process

- Mold design: Create a high-precision mold according to motor dimensions.

- Metal melting and injection: Heat aluminum or magnesium alloys until molten, then inject under high pressure.

- Cooling and demolding: Rapid cooling to form stable structure.

- Post-treatment: Surface coating and anti-corrosion processes.

Optimization of Heat Dissipation

By using reinforcement rib designs and thermally conductive materials, die-cast housings can significantly improve motor cooling efficiency.

Case Comparison

The table below shows the performance differences between conventional and high-precision die casting:

| Parameter | Conventional Die Casting | High-Precision Die Casting |

|---|---|---|

| Dimensional Tolerance | ±0.2 mm | ±0.05 mm |

| Surface Roughness (Ra) | 6.3 μm | 1.6 μm |

| Heat Dissipation | Standard | Improved (20% higher) |

| Post-Machining Demand | High | Low |

Quality Control and Inspection Methods

Common Defects

- Porosity: Caused by trapped air.

- Shrinkage cavities: Result of uneven cooling.

- Cracks: Due to mold design or metal contraction issues.

Inspection Methods

- CT scanning: Detect internal defects.

- CMM (Coordinate Measuring Machine): Ensure dimensional accuracy.

- Ultrasonic testing: Identify internal cracks.

Surface Treatment

Common processes include sandblasting, anodizing, and electrophoretic coating, which enhance corrosion resistance and aesthetics.

Industry Trends and Future Development

Exploration of New Materials

The combination of magnesium alloys and composite materials will drive further lightweight development of electric bicycles.

Smart Manufacturing and Automation

Future die casting production lines will integrate robotic arms and AI-based inspection systems, significantly improving consistency and yield rates.

Environmental Protection and Sustainability

Adopting low-energy melting technology and scrap recycling will be key to sustainable die casting.

Next-Generation Motor Outlook

Future motor housings will be more integrated, lightweight, and intelligent, further improving vehicle performance.

English

English Español

Español Deutsch

Deutsch русский

русский