1. Introduction: Understanding the Importance of Motor Housing Die Castings

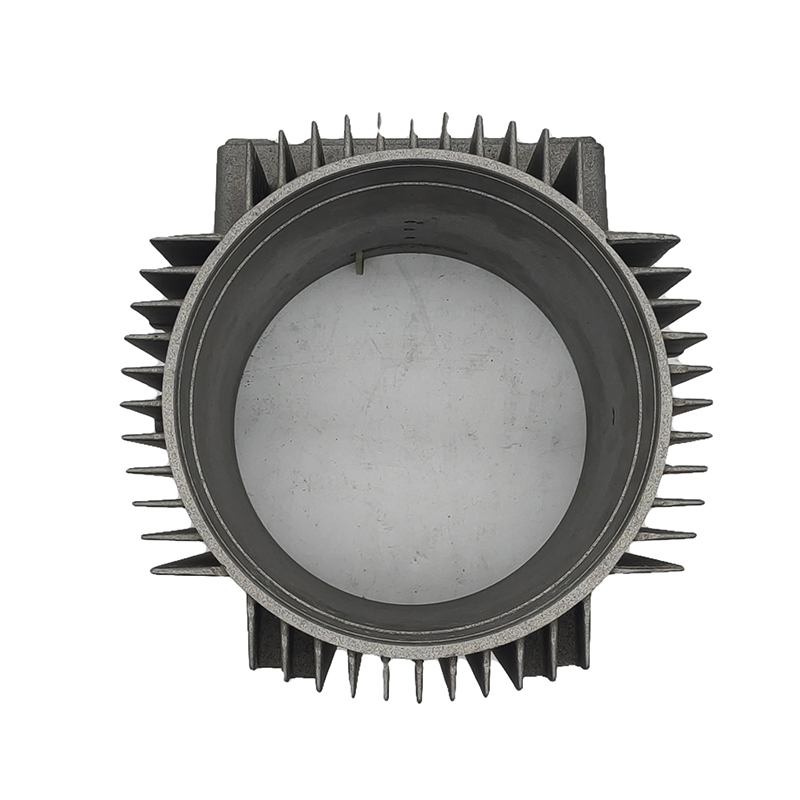

Motor Housing Die Castings are a crucial component in the design and manufacturing of motors. They not only protect the internal components of the motor but also have to withstand external environmental challenges, such as vibrations, temperature fluctuations, moisture, dust, and other corrosive materials. Therefore, the quality of the motor housing directly impacts the motor’s overall performance, lifespan, and reliability.

Die casting is a process where molten metal is injected into a mold and solidifies to form a part. In motor manufacturing, the housing is a key part, and the quality of its casting significantly affects the motor’s function. To ensure high-performance motors, choosing and manufacturing high-quality Motor Housing Die Castings is crucial.

2. Common Production Issues and Their Impact

During the production of Motor Housing Die Castings, several common production issues can lead to a decline in the quality of the motor housing, and even directly affect the motor’s performance.

2.1 Casting Defects

Common casting defects include porosity, cracks, shrinkage, etc. Porosity typically occurs when gases get trapped inside the casting, which not only weakens the casting’s mechanical strength but may also affect the housing’s sealing ability. Cracks indicate that the casting couldn’t withstand external shocks or stresses, while shrinkage occurs due to the reduction in volume during the cooling of the metal, which can lead to surface imperfections or dimensional deviations.

2.2 Dimensional Precision Issues

Dimensional precision is a critical factor in casting production. Even the smallest dimensional error in the motor housing may affect its assembly or induce unnecessary mechanical stresses. Large dimensional errors may lead to assembly problems or compromise the overall structure of the motor, thus reducing its performance.

2.3 Surface Quality Issues

The surface quality of the casting is vital for both the appearance and practical application of the motor housing. Rough surfaces or defects can affect the appearance of the motor and reduce its market competitiveness. Additionally, a rough surface can also make assembly difficult or lead to friction during the motor’s operation, thereby reducing its efficiency.

2.4 Material Inhomogeneity

Material inhomogeneity in motor housing castings is a severe issue. If the material composition and structure of the casting are uneven, it may lead to cracks, deformation, or unstable performance during long-term use, affecting the motor’s reliability.

3. How to Choose High-Quality Motor Housing Die Castings

Choosing high-quality Motor Housing Die Castings is the key to ensuring the motor’s performance. Here are several important criteria for selection.

3.1 Material Selection

The material is the first and foremost factor that affects casting quality. Different casting materials are suitable for different motor requirements.

3.1.1 Aluminum Alloys

Aluminum alloys are one of the most commonly used materials for casting due to their excellent strength, corrosion resistance, and thermal conductivity. Aluminum alloy motor housings effectively dissipate heat, maintaining the motor’s stability in high-temperature environments, and are lightweight, making them ideal for applications requiring reduced overall weight.

3.1.2 Zinc Alloys

Zinc alloys are easier to process during casting and offer good mechanical properties. Zinc alloy housings are highly durable and wear-resistant, making them suitable for medium-load motor applications. However, their corrosion resistance and thermal conductivity are lower compared to aluminum alloys, so they are less suitable for high-temperature or harsh environments.

3.1.3 Magnesium Alloys

Magnesium alloys are known for their extremely low density, making them ideal for applications where weight reduction is crucial. However, magnesium alloys have poor corrosion resistance, so surface treatment is necessary to improve their resistance to corrosion.

3.1.4 Material Homogeneity

Material homogeneity is essential for the performance of the casting. When selecting high-quality alloys, it’s important to ensure the consistency of their composition to avoid uneven hardness or strength, which could impact the motor housing’s lifespan.

3.2 Precise Casting Processes

The precision of the casting process directly affects the quality of the casting. Choosing the right casting process can significantly reduce defects and increase the strength of the casting.

3.2.1 Die Casting vs. Gravity Casting

- Die Casting: Suitable for mass production, it produces castings with high precision and smooth surfaces, especially for aluminum alloys.

- Gravity Casting: More suitable for complex castings, although slightly less precise, it is ideal for small-batch production and can lower production costs.

3.2.2 Mold Design and Quality Control

Molds are critical tools in the casting process, as their design determines the shape and accuracy of the casting. High-quality molds should have good heat resistance and strength, ensuring the precision and surface quality of the casting.

3.3 Surface Treatment and Post-Processing

The surface treatment of the casting is crucial for both its appearance and performance. The motor housing’s surface needs to be smooth, aesthetically pleasing, and durable.

3.3.1 Surface Finish

Surface treatment processes like sandblasting, polishing, and anodizing can effectively improve the surface finish of the motor housing and enhance its corrosion resistance. Anodizing is particularly effective for aluminum alloy motor housings, as it improves durability and also enhances appearance.

3.3.2 Heat Treatment

Heat treatment processes adjust the hardness and strength of the casting, improving its resistance to deformation. In high-strength motor applications, heat treatment can increase the motor housing’s resistance to high temperatures and impact.

4. How to Solve Common Casting Defects

Casting defects are the primary issue affecting the quality of motor housing castings. Below are some common defects and their solutions.

4.1 Porosity

Porosity is one of the most common defects in casting, usually caused by gases getting trapped inside the casting. Solutions to porosity include:

- Increasing the casting temperature to improve the fluidity of the metal.

- Enhancing the mold’s ventilation to reduce gas buildup.

- Using high-quality release agents to prevent gas from being trapped during casting.

4.2 Cracks and Shrinkage

- Cracks: Cracks usually occur during the cooling process due to uneven shrinkage of the metal. Solutions include adjusting the pouring speed, controlling the cooling rate, and preventing large temperature variations.

- Shrinkage: Shrinkage occurs during the solidification of the metal, leading to surface irregularities. Solutions include optimizing mold design, increasing the metal supply, and controlling the cooling speed.

4.3 Dimensional Issues

To reduce dimensional errors, precision casting processes and strict quality control must be adopted. Additionally, high-precision measuring equipment such as laser scanning and coordinate measuring machines (CMM) can ensure that the castings meet design requirements.

5. Quality Control and Inspection Methods

To ensure the quality of Motor Housing Die Castings, strict quality control and inspection are necessary. Below are some commonly used inspection methods.

5.1 X-Ray Inspection and CT Scanning

These non-destructive testing methods can detect internal defects such as porosity and cracks, ensuring the structural integrity of the casting.

5.2 Precision Measurement

Precision measurement is essential for ensuring that castings meet dimensional requirements. Common measurement tools include coordinate measuring machines (CMM), which provide high-precision measurement of various dimensions to ensure the casting meets design specifications.

5.3 Material Testing

Material testing usually includes hardness testing, tensile testing, and corrosion resistance testing. These tests ensure that the casting material meets the required performance standards, guaranteeing the motor housing’s long-term stability and reliability.

English

English Español

Español Deutsch

Deutsch русский

русский